Best Wattage for Laser Engraving

Laser engraving wattage plays a pivotal role in determining the speed, depth, and precision of the engraving process. Selecting the best wattage for laser engraving involves considering factors such as material type, thickness, and the desired engraving outcome.

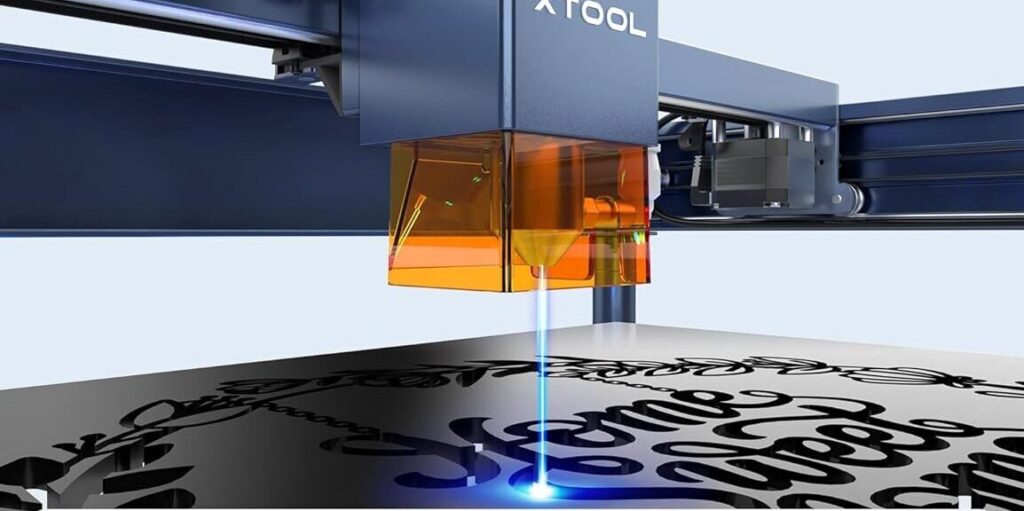

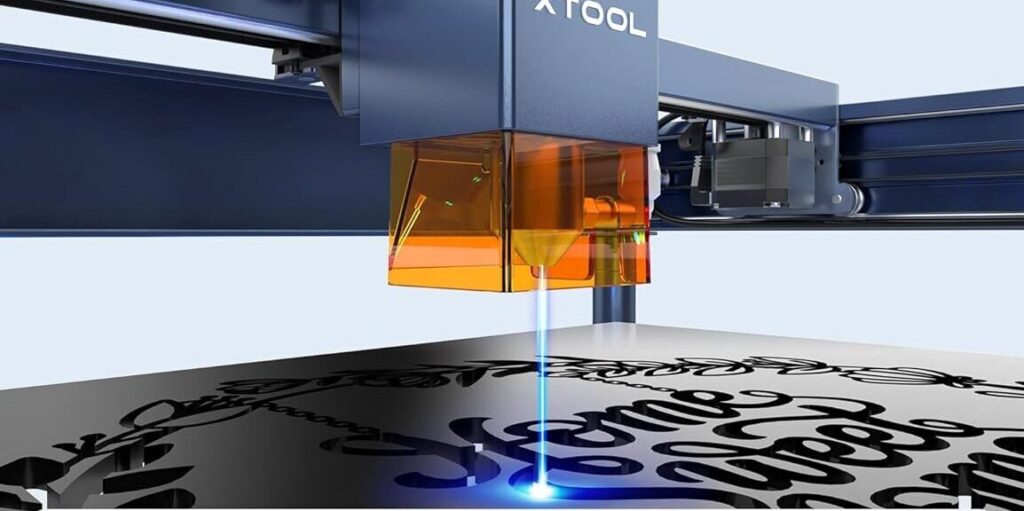

What is Laser Power?

Laser power directly regulates the energy from the laser head to cut various materials. Higher power levels enable the laser cutting machine to create high-quality results on thicker or harder materials. However, it’s essential to find the right balance between power, speed, and material to achieve optimal cutting outcomes.

What Are Some General Factors Influencing Laser Cut Power

Material Type and Thickness

- Different materials require varying power levels for optimal engraving outcomes.

- Soft materials like paper or leather demand lower power, while harder substances like metal necessitate higher power levels.

- Thicker materials may require additional power to achieve deep and striking engravings.

- Higher power levels are suitable for cutting thicker or harder materials efficiently and with high quality.

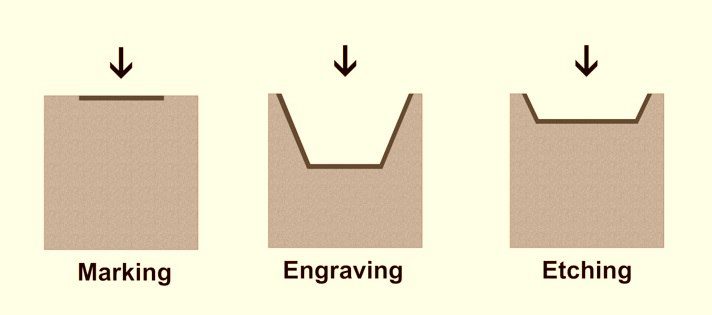

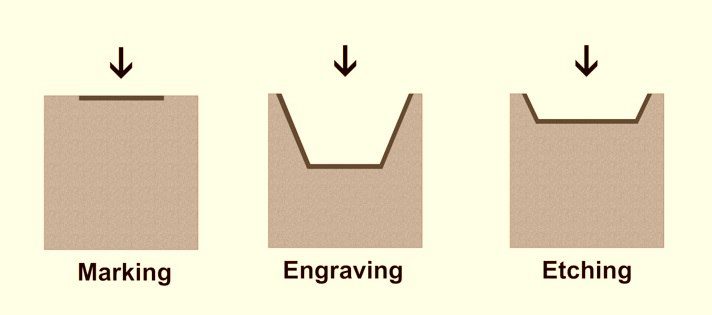

Engraving Depth and Speed

- The desired engraving depth and cutting speed determine the ideal power level for the laser engraver.

- Higher wattage lasers are suitable for achieving deep engravings swiftly, while lower wattage lasers are adequate for delicate engravings or slower cutting speeds.

- Laser cutting speed influences the energy acted on the material, affecting the quality of the cut and time efficiency.

Project Volume and Frequency

- Consider the volume of projects and the frequency of use when selecting the laser engraver’s power.

- Opting for a more powerful laser engraver enhances productivity and efficiency, especially for continuous, high-volume production.

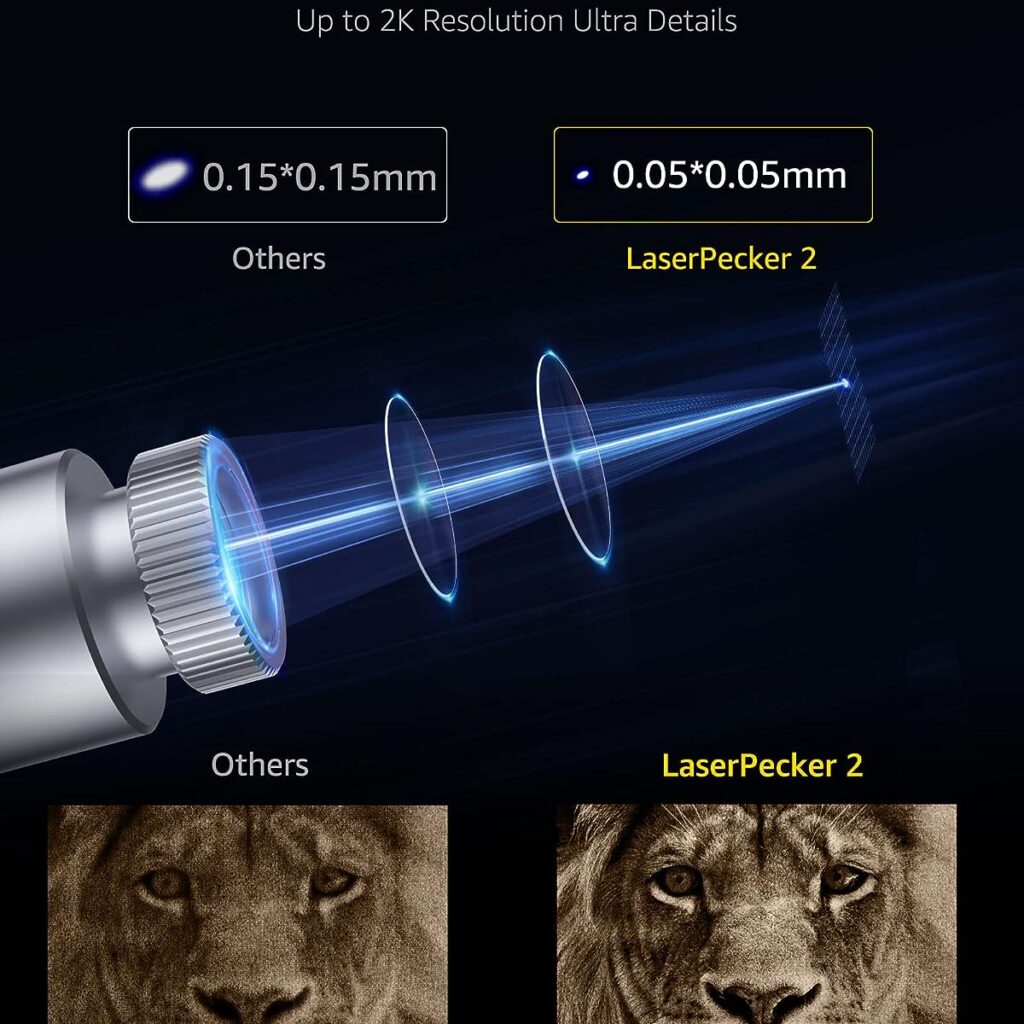

Precision and Detail

- Higher power laser engravers provide better control and precision, ensuring clean and accurate engravings for intricate designs.

Versatility

- Laser engravers with adjustable power settings offer flexibility to work with a wide range of materials and project types.

Recommended wattage for Laser Engraving

Low Wattage – Beginner Level (Under 30W)

- Ideal for delicate engraving tasks on materials like wood, leather, and thin acrylic. Low wattage provides fine detailing and intricate designs with minimal material removal.

- Tailored for hobbyists or beginners in laser engraving.

- Provides an excellent platform for experimentation and skill refinement.

Medium Wattage – Mid-Level (30W – 60W)

- A versatile range suitable for a wide array of materials, including wood, glass, thicker acrylic, some metals and certain plastics. Medium wattage strikes a balance between detail and speed, making it suitable for diverse engraving projects.

- Suitable for small businesses or individuals with moderate engraving needs.

- Strikes a balance between versatility and power.

High Wattage – Professional Grade (Above 60W)

- Suited for industrial-scale engraving and cutting tasks, high wattage lasers excel in processing thick materials, metals, and achieving rapid engraving speeds. This level of power is ideal for large-scale production and heavy-duty applications.

- Ideal for industries or businesses with high-volume and diverse engraving requirements.

- Offers exceptional speed and precision for extensive production and intricate designs.

Selecting the Best Wattage for Your Laser Engraver

It’s essential to consider material compatibility, project requirements, and machine capability when selecting the best wattage for your laser engraver.

Material Compatibility:

Assess the materials you frequently work with and their compatibility with different wattage ranges to achieve optimal engraving results.

| How much wattage do you need? | |

|---|---|

| Material | Engraving |

| Engrave most wood/cut 3mm | 3 |

| Engrave all/ cut up to 5mm of wood at a very slow speed | 5-6 |

| Cut 2cm wood & 3cm acrylic | 10 |

| Leather | 20 to 40 |

| Paper | 25 |

| Acrylic (3mm) | 30 |

| Stamp (2.3mm) | 30 |

| Anodized aluminum | 30 |

| MDF | 40 |

| Glass and ceramic | 40 to 60 |

| Thicker and denser wood | 60 to 150 |

| Thin acrylic sheets | 40 to 60 |

| Thicker acrylic | 80 to 150 |

| Stainless steel, ceramics, stone | 25-80W/40-50W |

| Metal | 50 to 100 |

| Cutting/deep engraving metal | 100 to 200 |

Project Requirements:

Consider the specific requirements of your engraving projects, such as speed, precision, and depth, to determine the most suitable wattage for each task.

Machine Capability:

Understand the power limitations and capabilities of your laser engraver to ensure that the selected wattage aligns with the machine’s specifications.

Conclusion

In conclusion, the best wattage for laser engraving is a nuanced consideration that depends on the specific requirements of your projects, the materials being processed, and the desired outcome. By understanding the optimal wattage range for different materials and applications, you can elevate the quality and efficiency of your laser engraving endeavors.