Transfer The Most Meticulous Designs to a Material thanks to

Laser Engraver

Did you know that laser engraving machines can engrave on a wide range of materials, including wood, metal, glass, and more. This engravers are perfect for unleashing your creativity and transforming ordinary items into extraordinary works of art. Learn on our website everything you need to know about laser engravers.

What Can you Find in Laser Engraver Pro?

Browse our categories, in which we offer you verified and current information on laser engraving and laser engravers:

There are three main types of lasers: Diode, CO2, Fiber

Best laser engravers for different materials

The most recognized brands of laser engravers

Here you’ll find detailed reviews, expert ratings and user reviews.

Tutorials, guides and answers to the most common questions related to laser engravers.

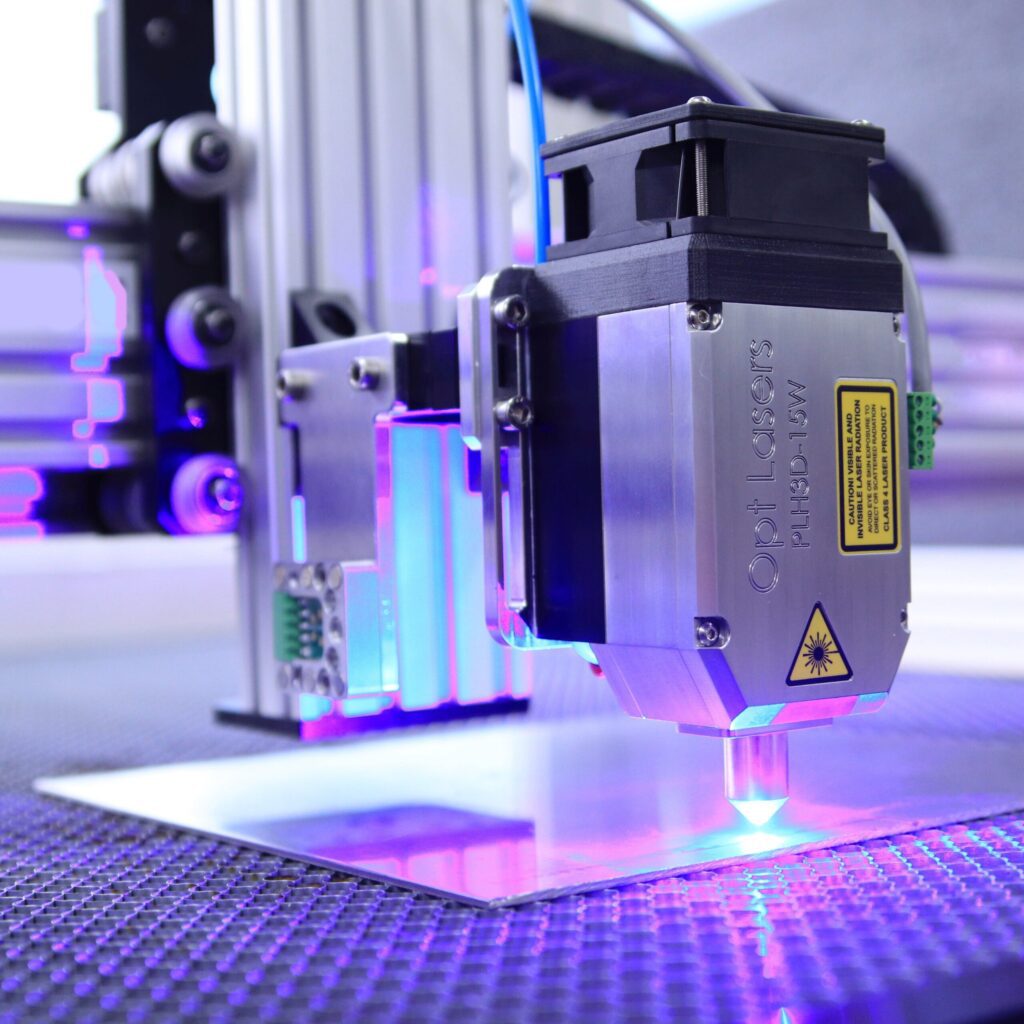

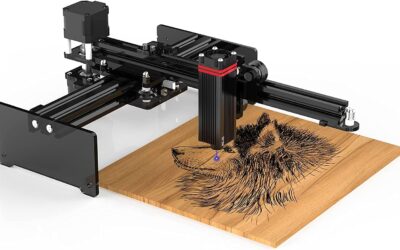

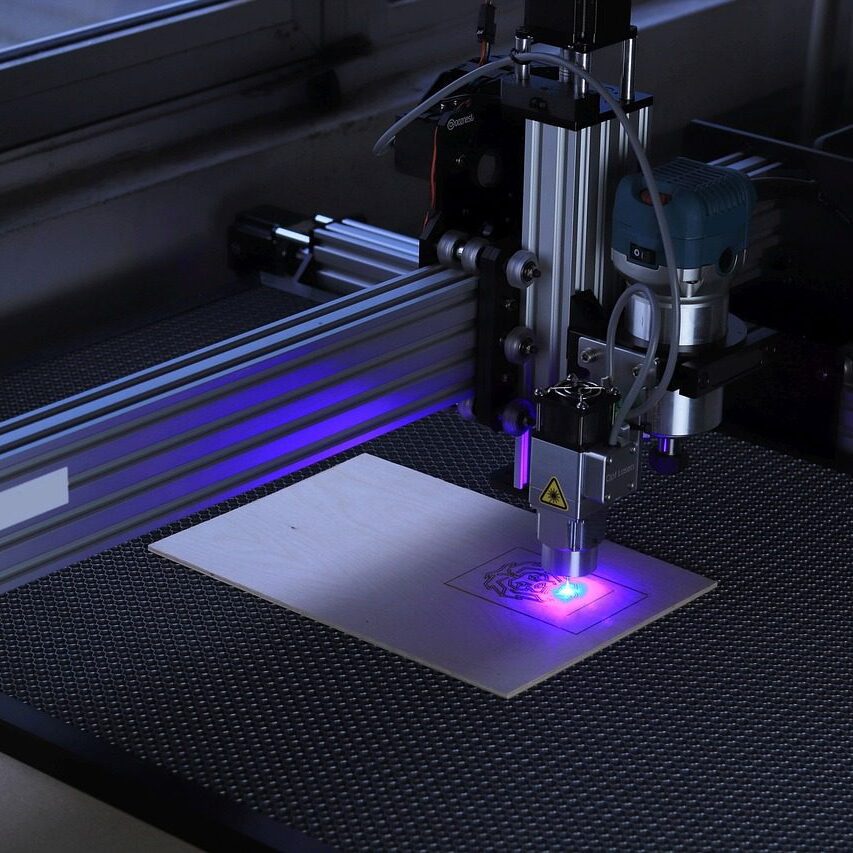

WHAT IS A LASER ENGRAVER

A laser engraver is a machine that uses a laser beam to etch, mark or engrave designs on various materials such as metal, wood, glass, plastic, and leather. By vaporizing the surface of the material, the laser beam creates a permanent and precise mark.

Laser engravers offer several benefits, including high precision and accuracy, versatility, and speed. They are commonly used for personalizing items such as trophies, jewelry, and electronic gadgets, as well as for industrial applications such as marking and labeling products. Additionally, They can can be utilized to create intricate designs, logos, and text on a wide variety of materials.

Advantages and Disadvantages

Advantages

- Laser engravers offer exceptional precision, allowing for intricate and detailed designs on various materials.

- They can be used on a wide range of materials, including wood, metal, glass, acrylic, leather, and more.

- Laser engraving is a fast process, enabling quick turnaround times for projects.

- It allows for personalized and unique designs, making it perfect for gifts, promotional items, and branding.

- Laser engravings are permanent and resistant to fading, ensuring long-lasting and high-quality results.

- Lasers can be automated, reducing labor costs and increasing efficiency in mass production or large-scale projects.

Disadvantages

- Lasers can be expensive to purchase and maintain.

- They require safety measures like eye protection and proper ventilation.

- this machines need regular maintenance and cleaning to ensure optimal performance and longevity.

Overall, the advantages of a laser engraver, such as precision, versatility, and speed, outweigh the disadvantages. With proper training and safety precautions, a laser engraver can be a valuable tool for businesses and individuals looking to add a touch of creativity and personalization to their projects.

WHAT TYPE OF LASER ENGRAVER TO BUY?

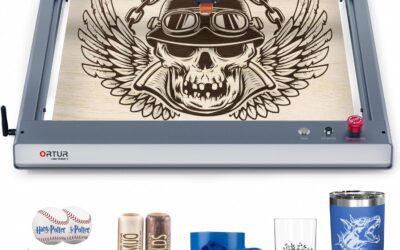

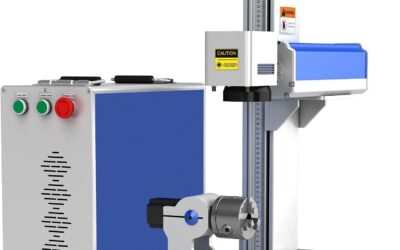

DIODE

A diode laser engraver is a versatile and affordable tool used in various industries for precision engraving. It uses a laser beam emitted by a diode to etch designs, text, or images onto a wide range of materials such as wood, plastic, leather, and metal.

CO2

A CO2 laser engraver is a device that uses a carbon dioxide laser to engrave or cut materials with high precision. It works by emitting a focused beam of infrared light that heats and vaporizes the surface of the material, creating a permanent mark or cut. This technology is widely used in various industries, including manufacturing, jewelry, signage, and crafts.

LASER ENGRAVER REVIEWS

Here you’ll find detailed reviews, expert ratings and user reviews, all to help you choose the perfect laser engraver to fit your needs.

Comparisons of engravers

Make informed decisions with our comparisons of laser engravers. Get to know the opinions of Professional or hobbyist, learn about the best brands and models, and discover which one best suits your needs.

HOW DO I CHOOSE A LASER ENGRAVING MACHINE

There’s no universally perfect laser for everyone, selecting the right laser engraver involves considering factors such as the materials you intend to work with, your budget, the required wattage, and the size of the machine. By answering these key questions, you can narrow down your options and find a laser engraver that perfectly suits your needs.

1. What are you trying to engrave or cut?

| ENGRAVE | CUT | LASER RECOMMENDED |

|---|---|---|

| Solid wood, plywood, MDF Leather, paper, some opaque acrylic, dark glass. Stone/Ceramic/Jade/Marble/Shale/Cement/Brick Plated metal/Coated metal, fabric. | Plywood, MDF, felt, leather, paper, and some dark acrylic. | DIODE |

| Acrylic (all colors)/Plastic, solid wood/Plywood, MDF, leather, paper, Glass, rubber, Stone/Ceramic/Jade/Marble/Shale/Cement/Brick, Plated metal/Coated metal, fabric. | Acrylic (all colors)/Plastic, Wood/Plywood, MDF, Fabric, Leather, Paper, Foam, Glass, Rubber. | CO2 |

| Aluminum, copper, painted metal, brass, ceramics, tungsten, chrome, fiberglass, carbon fiber, nickel, stainless steel, plastics, rubber, silver, gold, and synthetic leather. | Sheet metal, carbon steel, stainless steel, copper, brass, aluminum and titanium. | FIBER |

IMPORTANT

- A diode or a CO2 laser is required for processing organic materials.

- CO2 laser machines are better than diode laser machines in terms of cutting materials, they can cut and engrave the majority of non-metals.

- Fiber lasers are able to cut and engrave most metals and some non-metals.

- Stainless steel can also be etched by a diode laser and CO2.

2. What is your budget?

| TO ENGRAVE ORGANICS | (Wood, acrylic, glass and more.) | ||

|---|---|---|---|

| LASER | PRICE | RECOMMENDATION | |

| Diode laser | Under 1000 | Xtool D1 Sculpfun s5/ s9 Ortur master3 Neje 3 max v2 Atomstack X20 Omtech B10 Laserpecker 2 Atezr L2 36 W | |

| Budget CO2 | 2000-6000 | Omtech Monport | |

| Desktop CO2 | 3000 – 8000 | Glowforce Pro Gweike Cloud Pro-2 Flux beamo Xtool P2 OMTech Polar | |

| High end CO2 | 5000 – 15k | Aeon Mira 9 Thunder nova FSL PS20 Pro |

Check our picks for the BEST DIODE & BEST CO2 laser engravers

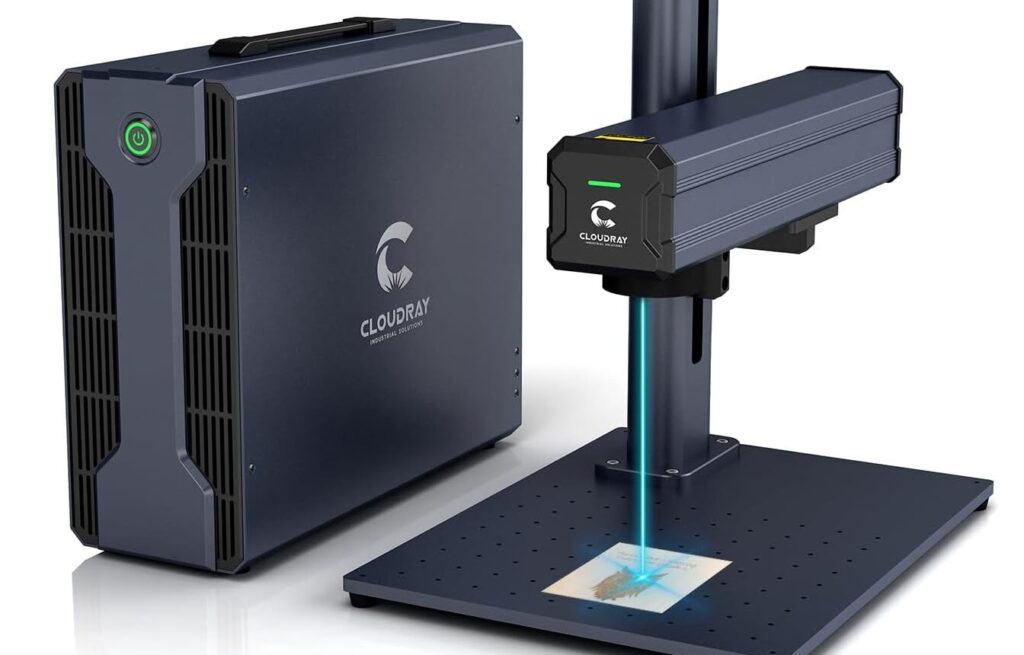

| TO ENGRAVE METAL | ||

|---|---|---|

| LASER | PRICE | RECOMMENDATION |

| Desktop fiber | 1000-2000 | Atomstack Xtool f1 Gweike 62 Monport gr |

| Budget industrial | 2000-3000 | Cloudray qs Em smart |

| High-end industrial fiber | 5000- 12k | Aura Nova |

- When considering your budget for a laser engraver, it is important to balance your needs with the available options.

- While higher-priced engravers may offer more power and advanced features, they may not be necessary for all projects.

- Engraving machine prices can vary from as low as $200 to well over $10,000.

- All the laser machines priced under $1,000 will be diode lasers.

3. How much wattage do you need?

| Material | Wattage | Type of laser |

|---|---|---|

| Engrave most wood/cut 3mm | 3W | Diode laser |

| Engrave all/ cut up to 5mm of wood at a very slow speed | 5-6W | Diode laser |

| Cut 2cm wood & 3cm acrylic | 10W | Diode laser |

| Leather | 20W to 40W | CO2 laser |

| Glass and ceramic | 40W to 60W | CO2 laser |

| Thicker and denser wood | 60W to 150W | CO2 |

| Thin acrylic sheets | 40W to 60W | CO2 |

| Thicker acrylic | 80W to 150W | CO2 |

| Stainless steel, ceramics, stone | 25-80W/40-50W | CO2/fiber |

| Metal | 50W to 100W | Fiber laser |

| Cutting/deep engraving metal | 100W to 200W | Fiber laser |

- Acrylic is a popular material for laser engraving. For engraving or cutting thin acrylic sheets, a laser with a wattage of 40W to 60W is recommended. Thicker acrylic may require a higher-wattage, around 80W to 150W.

- Engraving on glass is challenging due to its high melting point. A laser engraver with a wattage ranging from 20W to 60W, equipped with a specialized attachment for glass engraving, is recommended.

- Metal engraving typically requires higher-wattage lasers due to the material’s high melting point and conductivity. For engraving on thin metal sheets, a laser with a wattage of 50W to 100W is generally suitable. However, for cutting or deep engraving on metal, a higher wattage laser, ranging from 100W to 200W, is necessary.

Note : These wattage ranges are approximate and can vary depending on the specific laser engraver and manufacturer.

What else do I need to know before buying a laser engraver and cutter?

It is essential to consider other factors such as the work area, machine size, maintenance needs, and software compatibility. To make an informed decision, we recommend checking out our comprehensive reviews and detailed comparison of the most popular laser engravers in the market.

clear all your doubts

These are some of the most common questions about laser engravers.

The cost of a laser engraver varies widely, ranging from a few hundred dollars for entry-level models to several thousand dollars for professional-grade machines. Here you can read How much does a laser engraver cost?

Diode laser engravers are an ideal choice for beginners and small-scale projects due to their compact size and affordability. Entry-level laser engravers from brands like xtool , Ortur, and NEJE are popular choices for beginners due to their user-friendly interfaces and affordable prices. Best laser engraver for beginners

While affordable laser engravers exist, their quality and capabilities may be limited. Consider your needs and long-term goals before opting for a cheap model. Are cheap laser engravers worth it?

Laser engravers consume varying amounts of electricity depending on their power and usage, but they are generally energy-efficient.

Yes, laser engravers can etch intricate designs on glass, making them suitable for creating personalized glassware, awards, or decorative items. How To Laser Engrave Glass Safety and Effectively?

It’s not recommended to laser engrave materials like PVC, vinyl, or other chlorinated plastics due to the release of toxic fumes when burned. Laser Engraver ▷ What it is for, and what it is not for

With the right market and business strategy, running a laser engraving business can be profitable, especially when offering unique or personalized items.