According to our analysis, the best laser engraver for aluminium is

Can a Laser Engraver Engrave Aluminum?

YES, Laser engraving on aluminum offers endless possibilities for customization and personalization, due to its exceptional properties, including corrosion resistance, light weight, durability, and cost-effectiveness. The rise in demand for aluminum has led to a significant need for aluminum laser engraving for permanent marking and identification of different parts, items, and components.

Involves utilizing powerful laser beams to vaporize particles off the metal surface, creating deep marks without generating liquid residue where the material changes directly from solid to gas. This process allows for precise engraving without affecting the metal’s properties or appearance.

BEST LASER ENGRAVERS FOR ALUMINIUM COMPARISON CHART

| Laser | Omtech 20W | Cloudray 50W JPT | Laserpecker 3 | AtomStack M4 | Xtool D1 Pro |

|---|---|---|---|---|---|

| Picture |   |   |   |   |   |

| Type | Fiber | Fiber | Fiber | Fiber | Diode |

| Form factor | Portable | Portable | Handheld | Handheld | Portable |

| Recommended for | Hobbyists and jewelers | commercial A. marking machine | Professional or hobbyist | Hobbyists and jewelers | Hobbyists and crafters |

| Power | 20W | 30W | – | 20W | 20W |

| Engraving Area | 110×110 mm | 300x300mm | 100Y200mm | 70×70 mm | 430mm x 390mm |

| Speed | 7000 mm/s | ≤7000mm/s | 48000 mm | 12000 mm/s | – |

| Customer Ratings | 3.8/5 | 4.1/5 | 4.1/5 | 4.3/5 | 4.4/5 stars |

| Market price | $2700 | $5889 | $1799 | $1300 | $1200 |

| View on Amazon | View on Amazon | View on Amazon | View on Amazon | View on Amazon |

How do we make the comparison?

- We analyze the reliability of a laser machine based on user satisfaction, rating them on a scale of 1 to 5.

- We studied customer reviews to determine the most valued feature and most common drawback of each machine.

- We provide you with a detailed analysis of the specifications and accessories of each product, ensuring you have all the information you need.

ANALYSIS OF BEST ALUMINIUM LASER ENGRAVERS

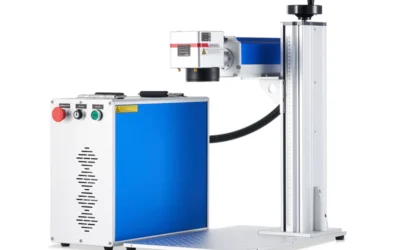

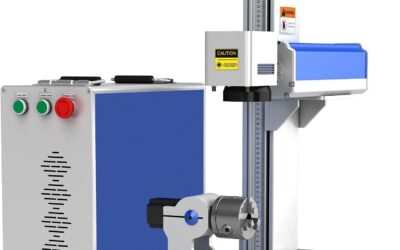

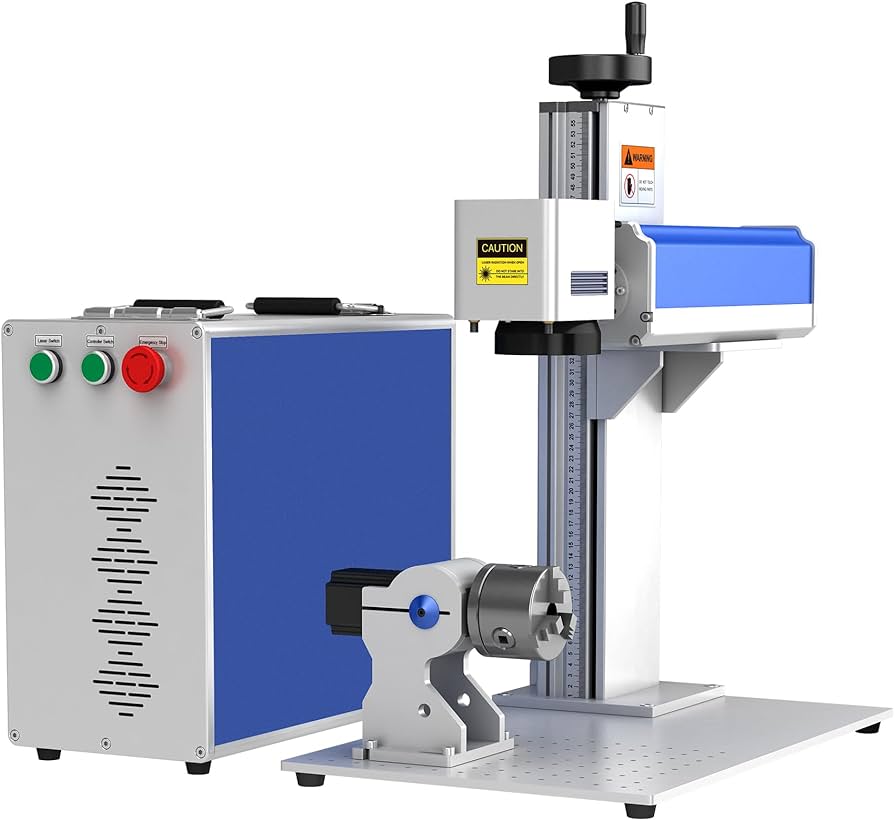

BEST ALUMINIUM ENGRAVING MACHINE: CLOUDRAY 50W JPT FIBER LASER

The Cloudray is considered the best value fiber laser due to its fast and powerful laser marking capabilities, making it suitable for high production volume and intricate work that requires fine detail. The Cloudray Laser can mark a wide range of materials, including metals, plastics, glass, and ceramics.

WHAT WE LIKE

1. Fast and powerful laser marking capabilities for high production volume and intricate work.

2. Removable workbench.

3. Comes equipped with a rotary tool.

4. The machine boasts a compact Fθ field lens with air spacing design and a protective anti-reflective coating.

COULD BE BETTER

1. Operating the machine may have a learning curve.

2. Requirement of additional equipment for specific needs.

3. Shipping expenses for separate orders.

BEST BUDGET-FRIENDLY LASER ENGRAVER FOR ALUMINIUM – MR. CARVE M1

MR.CARVE M1 Fiber Pro Laser Marking Machine,for All-Metals&Jewelry&Plastics…

- The world’s lightest 1064nm IR fibre marking machine.

- More cost effective, more versatile and aesthetically pleasing

- Electric lift, precise Focusing

- Exclusive case, shockproof and drop-proof easy to carry out

- 180° Explores a comprehensive view

- Easy To Install AND FAST TO USE

$1179.00

WHAT WE LIKE

1. Fast: The M1 is known for its exceptional speed.

2. Powerful: the M1 uses an infrared pulse laser with a wavelength of up to 1064nm, which provides excellent penetration. It can produce clear and precise engravings on stainless steel.

3. Safe: does not generate harmful blue light that can damage the eyes or cause harm if accidentally touched.

4. Portability and Usability: Despite weighing 6kg, the M1 is considered portable compared to heavy industrial-grade metal engraving machines that can weigh up to 50kg.

5. Use: Setting up the M1 is easy, requiring minimal assembly and no complicated cable connections.

COULD BE BETTER

1. App Limitations: it requires connection to a computer and manual parameter adjustments.

2. Performance on Curved Surfaces: The M1 may have less consistent engraving results on curved surfaces due to the high precision focusing of the pulse laser.

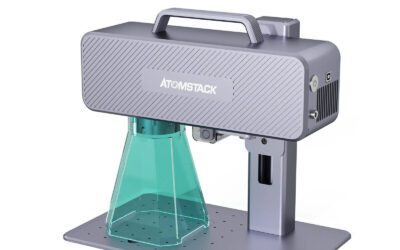

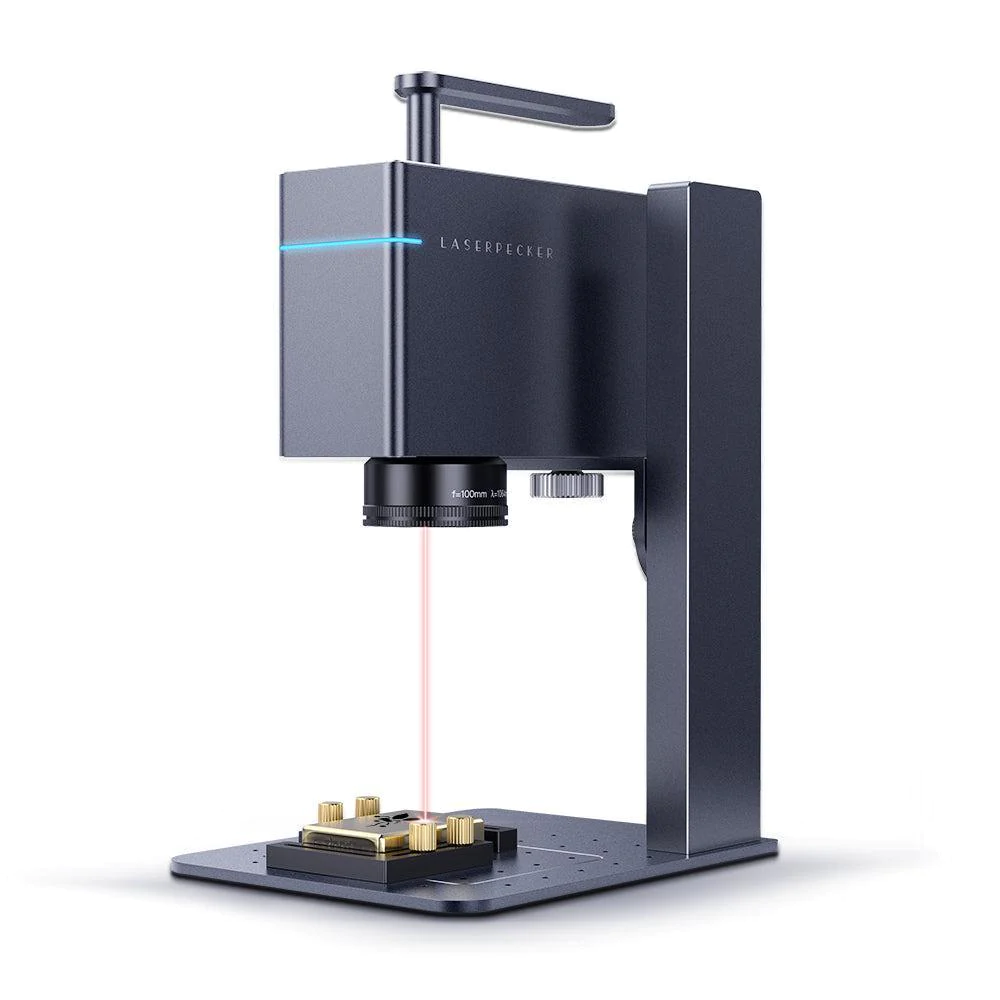

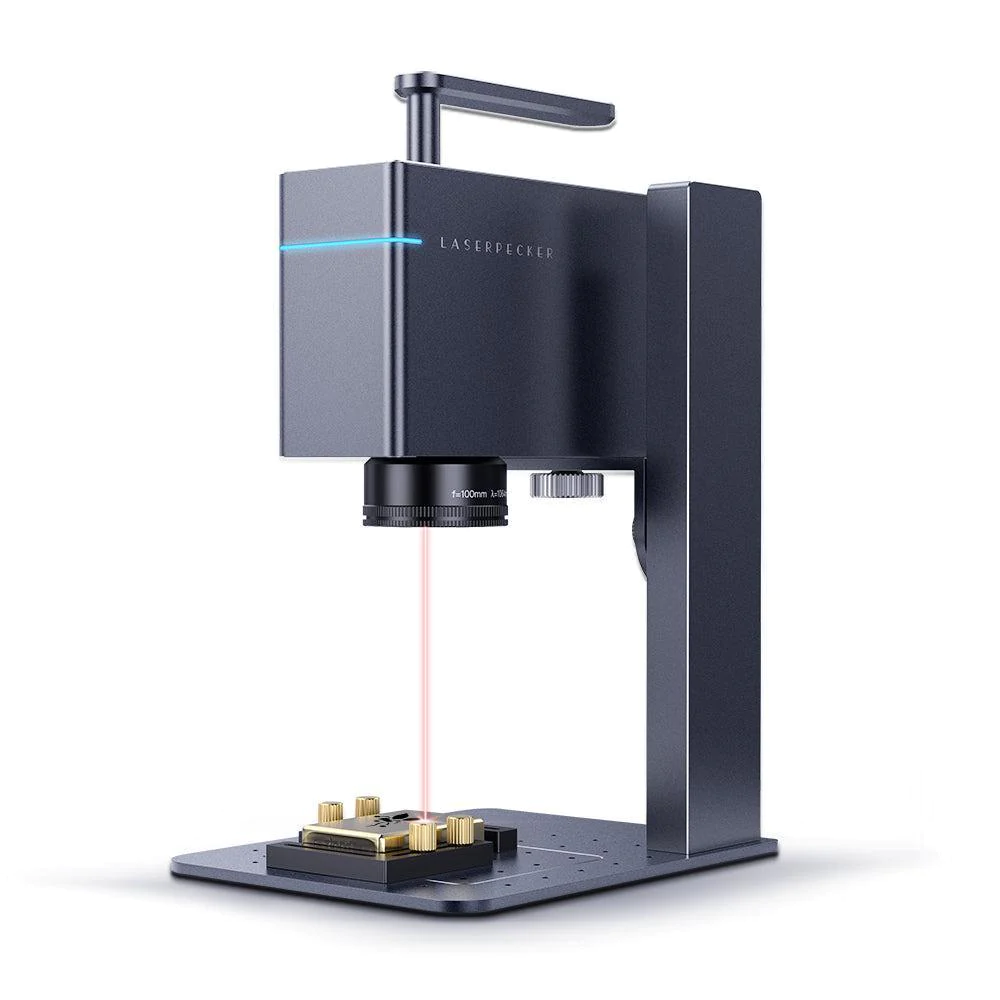

BEST PORTABLE LASER ENGRAVER FOR ALUMINIUM– LASERPECKER 3

LaserPecker 3(Deluxe) Laser Engraver for Metal 1064nm Pulsed Infrared Fiber..

- The Ultimate Pulsed Infrared Laser

- Fast Engraving Speed

- Ultra-Fine 4K Engraving Effects

- Ultra-High Accurate Positioning

- Profesional Laser Marking Machines for Metals and Plastics

- Compact and Convenient Storage

- 360° Rotary Engraving

$1439.99

WHAT WE LIKE

1. User-friendly experience and minimal technical knowledge required.

2. Precise and fast engraving on metal and plastic materials.

3. Wide compatibility with various materials.

4. User-friendly app interface.

5. Compact and stylish design.

6. Easy setup and Bluetooth connectivity.

COULD BE BETTER

1. Engraving limitations

2. Limited work area

3. Limited power

4. Limited functionality in the app

Good Laser Engravers for Engraving Aluminum

The two main types of lasers used in aluminum engraving are fiber laser systems and CO2 lasers, each offering distinct advantages in terms of material interaction and versatility.

LASER ENGRAVING DIFFERENT TYPES OF ALUMINUM

Bare Aluminum: Original state without exterior coating.

Anodized Aluminum: Coated bare aluminum with enhanced corrosion resistance and available in various colors.

- CO2, diode, and fiber laser engravers are all suitable for engraving anodized aluminum, offering hassle-free results without the need for pretreatment.

- Diode lasers are a cost-effective option for engraving anodized aluminum, providing excellent results in a single pass, with consideration for coating thickness.

Powder-coated Aluminum: Coated using a dry process, cost-effective, and environmentally friendly.

- CO2, diode, and fiber lasers can all engrave powder-coated aluminum without requiring pretreatment due to the material’s ability to absorb laser beams.

LASER ETCHING VS LASER MARKING ON ALUMINUM

Laser Etching Aluminum

this method involves using high-powered lasers to remove the anodized coating on aluminum, creating a high-contrast, permanent mark. This process is ideal for creating intricate designs and detailed artworks on aluminum surfaces.

Laser Marking Aluminum

Laser marking, on the other hand, uses low-power lasers to create a contrasting mark on the surface of the aluminum, without removing any material. This method is perfect for adding serial numbers, barcodes, and logos to aluminum parts and products.

PROS AND CONS OF ALUMINUM LASER MARKING

Pros

- Permanent markings, increased efficiency, precise marks, eco-friendliness in some machines, and reduced risk of counterfeit parts in the supply chain.

- Part marking enables accurate tracking of components through marked QR codes, data matrix codes, or serial numbers, essential for quality control and supply chain functions.

- Differentiating similar parts, facilitating part assembly, linking parts/products to the manufacturer, and simple labeling are additional reasons for part marking.

- Simplify design to reduce cost, submit designs as vector files to maintain quality, include all required marking dimensions in the final submission, and specify the location for the marking.

Cons

- Requires a high level of operator skill, variable production speed and energy usage, and potential release of hazardous fumes.

- Upfront costs, maintenance costs, and the cost of operation for laser engraving can be high.

KEY CONSIDERATIONS WHEN CHOOSING AN ALUMINUM LASER ENGRAVER

When considering aluminium engraving, it’s essential to evaluate whether it’s the only material you want to engrave due to the significant differences in intrinsic properties between metals and other materials. If exclusive metal engraving is the goal, a fiber laser is recommended. These lasers are optimized for metal frequencies and come in various intensities, efficiently marking and cutting thin metals.

MATERIAL COMPATIBILITY

Laser Engraving Bare and anodized Aluminum: Fiber lasers are suitable for engraving both bare and anodized aluminum, while CO2 lasers require pretreatment for bare aluminum but can engrave anodized aluminum with ease.

- Fiber Laser: Suitable for direct engraving without pretreatment. They have a higher upfront cost, they offer lower operational costs, higher speed, and extended lifespan.

- CO2 Laser: Requires special pretreatment or a metal marking compound. They are a more affordable option and can engrave a wide range of materials, making them suitable for laser engraving businesses.

- Diode Laser: Requires pretreatment and multiple passes for visible results. They are the most cost-effective solution for engraving anodized and powder-coated aluminum, offering versatility to engrave various materials.

PRICE

The price of powerful laser engravers can be a barrier, with fiber laser machines generally being more expensive due to their professional-grade nature. CO2 and diode lasers, while more affordable, align with their capability.

CAPABILITY ANALYSIS

Various factors contribute to a machine’s capability, including precision and accuracy, engraving size, materialversatility, and additional features such as a Z-axis or rotary module, showcasing adaptability and increased functionality.

PRECISION AND DETAILING

For intricate designs and fine detailing on aluminum, look for a laser engraver with high precision and intricate detailing capabilities. This ensures that your engravings are sharp, clear, and visually striking.

SPEED AND EFFICIENCY

The speed at which a laser engraver operates is crucial, especially for large-scale projects. Finding a balance between speed and precision is vital to ensure efficient and timely completion of your aluminum engraving tasks.

RELATED POST

FAQ

Laser engraving aluminum typically requires at least 20-30 watts for effective results, so a 5-watt laser may not be suitable for engraving aluminum.

A 5-watt laser can engrave some types of metal, but may not be suitable for engraving aluminum.

Similarly, a 10-watt laser is generally not powerful enough to cut aluminum effectively.

Fiber lasers are often considered the best machines for cutting aluminum due to their efficient interaction with metal materials.