Laser Engraver Safety Precautions

Laser engravers and cutters are multifaceted tools, used for cutting, marking, and engraving a variety of materials. As they become more affordable and versatile, they are increasingly employed in various applications. Laser engravers typically house a Laser Hazard Class 4 device, indicating their significant power and potential to cause permanent injury. We’ll explore the crucial safety measures to ensure safe and responsible operation of your laser engraving machine.

Safety Protocols

Safety should always be the top priority when operating a laser engraver, adhering proper protocols is paramount to safeguarding yourself, your workspace, and those around you.

To ensure safe operation of a laser engraver, it is imperative to establish proper setup, provide training, and implement engineering controls.

Before Use

- Users must complete online fire extinguisher training before utilizing the laser cutter.

- Regularly check and replace the filter in accordance with the manufacturer’s guidelines.

- All users should be trained on potential hazards, control measures, operating procedures, permissible materials, PPE, emergency procedures, and equipment cleaning.

- Wear necessary PPE, including safety glasses and heat-resistant gloves.

During Use

- Supervise the cutting or engraving process to prevent combustible materials from igniting.

- Maintain a clear area around the laser cutter, free of combustible materials.

- Have a properly maintained carbon dioxide (class B) fire extinguisher nearby.

- Only use materials approved by the manufacturer.

- Ensure all covers are in place and interlocks are functioning correctly.

- Allow the material to cool on the cutting bed before handling.

- Cease operation and notify the supervisor if the air filter or exhaust system malfunctions.

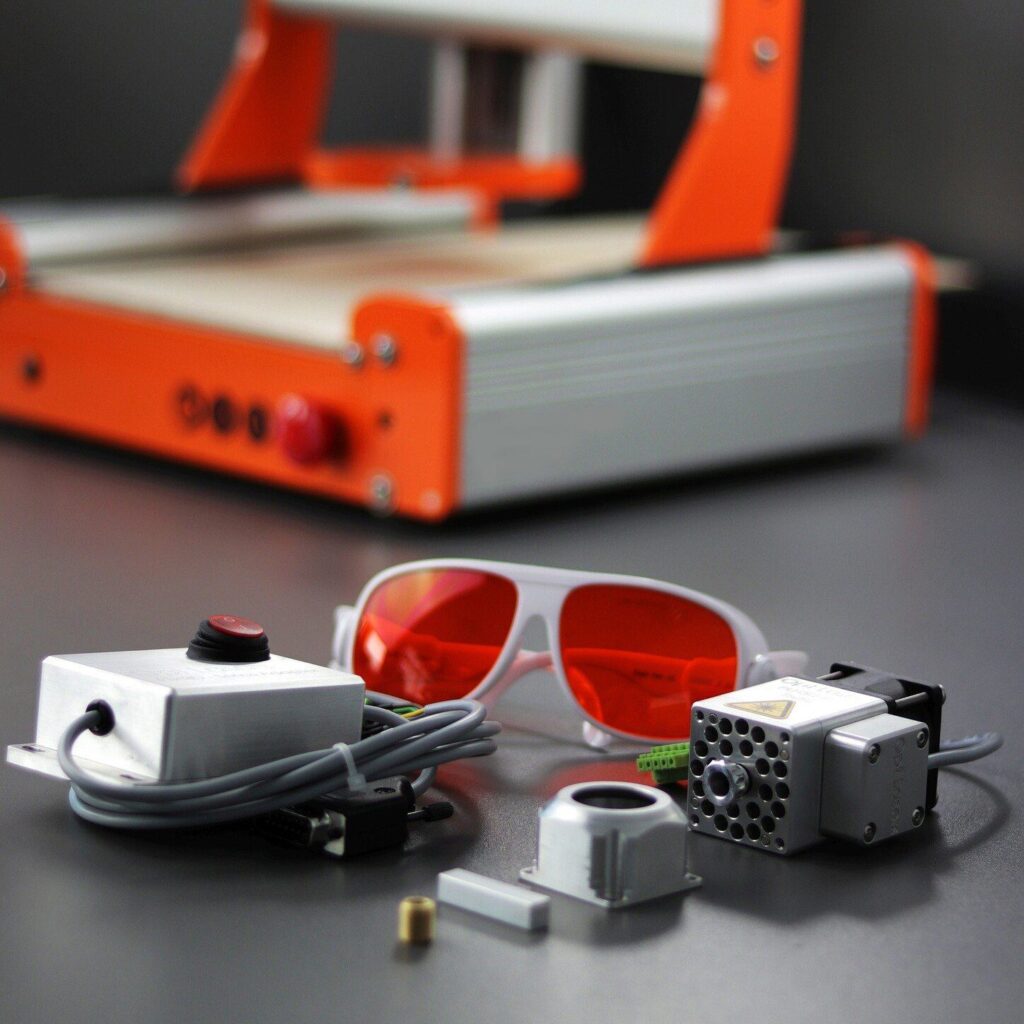

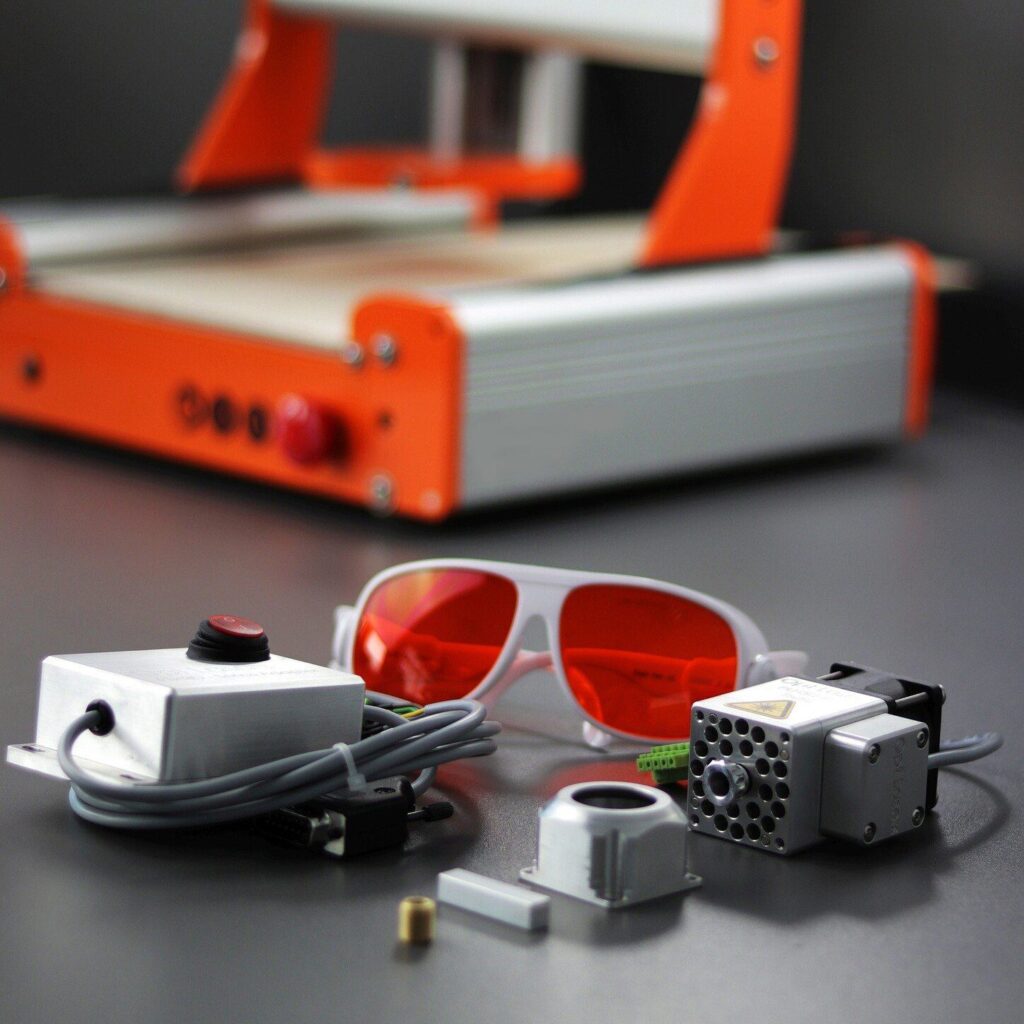

Essential Safety Precautions for Laser Engraver Operation

1. Protective Eyewear:

Prioritize the use of laser safety goggles specifically designed for the wavelength of your laser engraver. These goggles shield your eyes from laser radiation, reducing the risk of eye injuries.

2. Ventilation and Air Quality:

Ensure proper ventilation in your workspace to mitigate the accumulation of potentially harmful fumes and particulates produced during laser engraving. Consider using an exhaust system to remove airborne contaminants.

3. Fire Safety:

Keep a fire extinguisher rated for electrical fires(type c) within easy reach of your workspace. Additionally, refrain from leaving the laser engraver unattended during operation to minimize the risk of fire hazards.

4. Machine Maintenance:

Regularly inspect and maintain your laser engraving machine according to the manufacturer’s guidelines. This includes checking the alignment of laser optics, cleaning the machine, and ensuring all safety interlocks are operational.

5. Material Compatibility:

Familiarize yourself with the materials suitable for laser engraving and their associated safety considerations. Certain materials may emit toxic fumes or pose fire risks when subjected to laser engraving, necessitating careful evaluation and precautionary measures.

6. Workspace Organization:

Maintain a well-organized workspace to minimize the risk of accidents. Keep the area around the laser engraver clear of clutter, ensuring unobstructed access to emergency shut-off controls and other safety features.

Laser Engraver Hazards

- Fire/Hot Objects: Substrate materials generate significant heat during cutting and can ignite.

- Hazardous Vapors and Fumes: Specific materials can produce hazardous airborne contaminants, requiring proper exhaust and ventilation systems.

- Other Hazards: Exposure to the laser beam can cause severe eye damage or skin burns, while sharp edges can cause lacerations and puncture wounds.

Different Hazards according the type of machine

Diode Laser Hazards

A Diode Laser employs a semiconductor diode to create blue or green laser radiation. Laser radiation generated by a blue or green diode laser poses significant hazards. Light at 532 nm wavelength can pass through transparent materials such as the lens of the eye, directly impacting the retina and causing irreversible damage within milliseconds. Both blue and green laser light can inflict permanent harm to the eye, with blue light being particularly damaging.

CO₂ Laser Hazards

A CO2 laser cutter utilizes a glass tube filled with inert gases, linked to a high voltage power supply. Light is generated within the tube, emitting laser radiation from one end. This radiation is then directed through a series of mirrors until it reaches the laser head, where it is focused onto the workpiece for cutting or engraving.

CO2 lasers emit light at a wavelength of 10,600 nm in the infrared spectrum. Although this light is invisible, it is blocked by most materials, including the lens and cornea of the eye. When IR light interacts with an object, it heats the surface, enabling the CO2 laser to cut and engrave by vaporizing the material. While the rapid absorption of blue/green diode laser light can cause immediate eye damage, the slower absorption of CO2 laser light makes immediate harm less likely.

DO’S AND DON’TS

- Never operate the system unattended and always keep a properly maintained fire extinguisher nearby.

- Maintain a clutter-free area around the cutter and keep its interior clean.

- Do not modify or disable any safety features of the laser system.

- Use accepted materials only and never operate the laser if any safety interlocks are defeated.

- Keep a properly maintained fire extinguisher nearby and never defeat laser interlocks built into the cutter.

Educating Others on Laser Engraver Safety

If you operate a laser engraving business or frequently engage with others in your workspace, it’s crucial to educate them about laser engraver safety protocols. This includes providing thorough training on safe machine operation, the proper use of personal protective equipment, and emergency procedures.

In conclusion, prioritizing safety when using a laser engraver is imperative for every operator, whether a novice or seasoned professional. By upholding strict safety protocols, investing in protective equipment, and promoting a safety-oriented mindset, you can ensure the safe and responsible operation of your laser engraving machine.