CAN YOU LASER ENGRAVE ON PLASTIC?

Plastic, as a prevalent material in our daily lives, is often a top priority for laser enthusiasts due to its versatility and wide-ranging applications. So yes, you can laser engrave plastic.

Laser cutting and engraving machines are capable of working with plastic with exceptional precision and accuracy. However, it’s essential to note that not all types of plastics are suitable for laser cutting and engraving. Understanding the specific types of plastic suitable for these processes is crucial, as some plastics can emit toxic fumes.

How Laser Cutting Plastic Works

Laser cutting and engraving machines function by using a laser beam to heat the material to the point of vaporization or melting, resulting in a cut or engraved mark. The laser beam’s power, speed, and frequency can be modulated to achieve different effects and depths.

This technique harnesses the precision and power of a high-quality laser engraver to etch designs onto the surface of plastic materials, offering a wide array of creative possibilities for customization and personalization. Whether it’s creating custom name plates, signage, or adding intricate designs to promotional items, laser engraving on plastic is a transformative art form that empowers individuals to bring their unique visions to life.

Types of Plastic for Laser Cutting and Engraving

When it comes to laser engraving on plastic, various types of plastic materials can be effectively used to create intricate and durable designs. Plastics are commonly categorized into seven or eight categories, including acrylic, polycarbonate, PVC, polyethylene, polypropylene, PET, and ABS. These categories encompass various types of plastics that are suitable for laser cutting and engraving.

Acrylic (PMMA)

- Properties: Acrylic, also known as polymethyl methacrylate (PMMA), is a versatile and durable plastic material with excellent optical clarity.

- Suitability for Laser Engraving:

-Acrylic is one of the most popular materials for laser engraving due to its ability to produce high-contrast and detailed engravings.

-The laser engraving process results in a frosted appearance on the engraved areas, creating a visually striking contrast against the clear surface of the unengraved portions.

ABS (Acrylonitrile Butadiene Styrene)

- Properties: ABS is a thermoplastic polymer known for its toughness, impact resistance, and heat resistance.

- Suitability for Laser Engraving:

– ABS can be effectively laser engraved, producing durable and precise markings.

– The laser engraving process on ABS can yield clean and detailed engravings, making it suitable for a wide range of applications, including industrial and consumer products.

Polycarbonate

- Properties: Polycarbonate is a transparent thermoplastic known for its exceptional impact resistance and optical clarity.

- Suitability for Laser Engraving:

– Laser engraving on polycarbonate can produce high-precision and intricate designs, making it suitable for applications where optical clarity and durability are essential.

– The process of laser engraving on polycarbonate results in crisp and visually appealing engravings, ideal for signage, nameplates, and industrial applications.

Polyoxymethylene (POM) or Acetal

- Properties: POM, also known as acetal, is a strong and rigid engineering thermoplastic with excellent dimensional stability.

- Suitability for Laser Engraving:

– Laser engraving on POM can yield precise and permanent markings, making it suitable for applications that require high mechanical strength and chemical resistance.

– The engraved markings on POM exhibit sharp contrast, providing clear and durable identification for various industrial and engineering applications.

Polyethylene Terephthalate (PET)

- Properties: PET is a transparent and lightweight thermoplastic polymer with excellent dimensional stability and chemical resistance.

- Suitability for Laser Engraving:

– Laser engraving on PET can result in high-contrast and durable markings, making it suitable for applications such as labeling, signage, and decorative elements.

– The process of laser engraving on PET offers the ability to create intricate and detailed designs, adding a touch of personalization and customization to various products.

Best Plastics Suitable for Laser Cutting

Plastics such as acrylic, fluoropolymers, Delrin, Mylar, polyester, polystyrene, and polyurethane are commonly used for laser cutting and engraving due to their compatibility with laser machines and their non-emission of hazardous gases or particles.

Plastics Not Suitable for Laser Cutting

Certain plastics, such as PVC, ABS, carbon fiber, polycarbonate, and HDPE, are not suitable for laser cutting and engraving due to their emission of harmful fumes and vapors, which can pose serious health risks.

BEST LASER ENGRAVER FOR PLASTIC – XTOOL P2

When considering the material type for laser engraving plastic, a CO2 laser engraver is the most suitable option. CO2 lasers are specifically designed to work well with organic materials like plastic, providing precise and high-quality engravings.

The Xtool P2 laser engraver is the best option for Plastic engraving due to its precise capabilities and high-speed performance. Its compact size makes it suitable for small spaces, maximizing workspace efficiency. With a power output of 55W, it stands out as one of the most powerful desktop CO2 lasers available.

WHAT WE LIKE

1. Intuitive and easy-to-use software, enabling easy prototyping.

2. Close-up view and thickness measurement features for precise placement and focusing.

3. Camera feature for easy placement of multiple items on one sheet of material.

4. Versatile and capable of handling various materials and projects.

5. Large working area and double cameras for precision.

6. No annoying cloud subscription and lower price compared to competitors.

7. Excellent customer service and support from xTool.

COULD BE BETTER

1. Accessing the laser tube and coolant tank requires removing screws.

2. The mobile version of XCS software lacks some features.

3. Incompatibility with certain features in Lightburn software.

4. Inability to cut thin metal or engrave metal.

5. Possible need for adjustment of mirrors/lenses due to transport.

Other great options to consider: Xtool D1 Pro, OMTech Polar, Glowforge Aura and xTool F1

The cheapest: Xtool D1 Pro $1200

The most expensive: Xtool P2 $5000

Tips for Achieving Clean Cuts in Laser Cutting Plastic

- Opt for an Appropriate Laser Machine

- The quality of laser cutting plastic significantly relies on the chosen machine. Consider using a CO2 laser cutter with an optical power of at least 40W for optimal results. Low-power machines may lead to melting and inefficient cuts. Alternatively, a powerful diode laser is suitable for cutting acrylics up to 5-8mm.

- Fine-tune the Laser Focus

- A crucial aspect for achieving clean cuts is ensuring precise laser focus. Properly adjusting the focus according to manufacturer instructions and material thickness is vital.

- Conduct a Speed-Power Test

- When using a laser machine on a specific material for the first time, running a speed-power test can provide the optimal settings, saving time and material resources.

- Consider Multiple Passes

- For thicker materials, running multiple passes is preferable to running the machine at very low speed, as excessive heat can cause melting. This approach helps in achieving clean cuts without compromising the material.

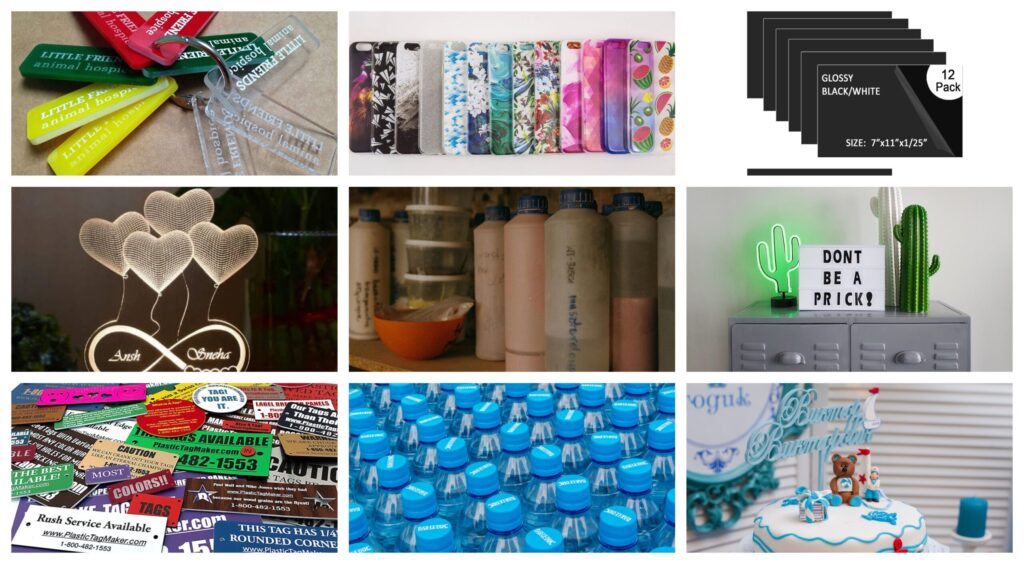

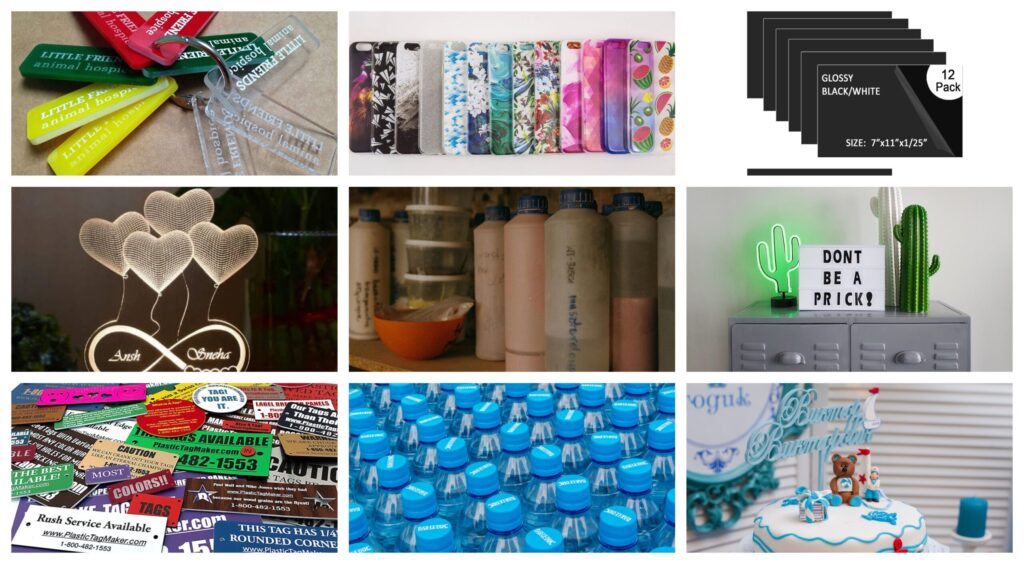

Laser Engraving Plastic Applications

- Plastic Bottles and Boxes, Laser engraving is utilized to add labels, logos, manufacturing dates, and expiration dates, enhancing product aesthetics and brand recognition.

- Laser Engraving on Phone Casings, decorative patterns on phone casings, providing a unique and personalized touch to phones.

- Laser Engraving on Plastic Signs and Advertising Boards.

- Laser Engraving on Furniture and Household Items, such as chairs and tables, resulting in attractive and elegant products.

- Laser Engraving Plastic Lamp

- Laser Cut Plastic Birthday Cake Toppers

- Laser Cut Plastic Home Decor Items

BUY NOW THE BEST LASER ENGRAVER FOR PLASTIC!!