top laser engravers FOR glass etching

Best Glass Engraving Machine

According to our analysis, the best laser engraver is xTool P2

TOP LASER ENGRAVERS FOR GLASS COMPARISON CHART

Based on our experience with engravers, we have prepared the following comparison table with the best alternatives available in 2024:

| Laser | Xtool P2 | Flux beamo | Xtool D1 Pro | Trotec Speedy 300 | Epilog Zing 24 |

|---|---|---|---|---|---|

| Picture |   |   |   |   |   |

| Type | CO2 | Diode | Diode | CO2 RF | CO2 |

| Form factor | Desktop | Desktop | Portable/open | High end | Desktop |

| Power | 55W | 30 W | 20W | 10 to 120W | 30 to 60W |

| Engraving Area | 600 x 308 mm | 300 x 210 | 430mm x 390mm | 610x 305 mm | 610x 305 mm |

| Speed | 600 mm/s | 300 mm | 400 mm | 3.55 m/sec | – Mm/sec |

| Highlights | A riser and a conveyer belt make this pretty unique. | Powerful, and great for etching simple designs and logos. | Overall great built quality and reliability | Mistral Exhaust, Auto Focus, Air Assist system, Trolley stand, Rotary Attachment, 2 lenses 1.5 & 2.0 | Digitally controlled, air-cooled CO2 laser tubes are fully modular, permanently aligned. |

| Issues | Spend extra to get more from the P2 | Software | Lack of integrated air assist | New software, a bit limited in functionality. | |

| Market price | $5000 | $2195 | $1200 | $25000 -$31000 | $14500 |

| Buy on Amazon | Buy on Amazon | Buy on Amazon |

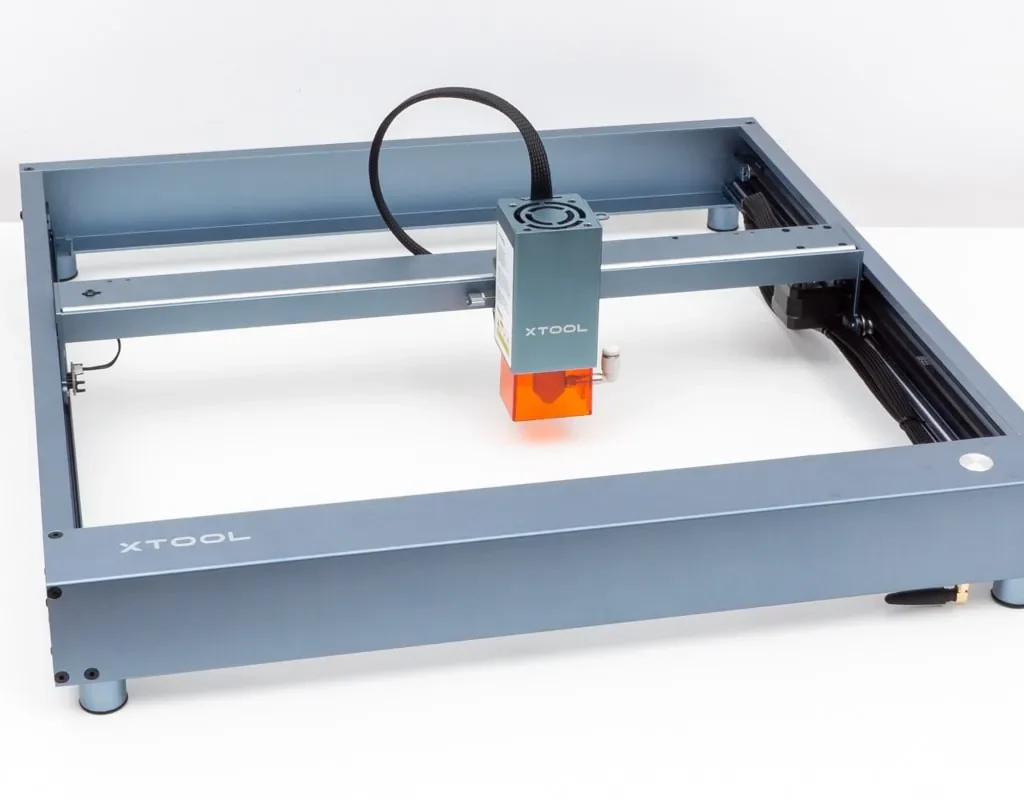

XTOOL P2 – BEST GLASS ENGRAVING MACHINE

The CO2 laser is considered the best laser engraver for glass etching due to its ability to deliver high precision and detailed results. With its focused beam and controlled heat, the CO2 laser ensures clean and accurate etchings on glass surfaces.

When it comes to finding the ultimate laser engraver for glass, The xTool P2 stands out as a top contender. This versatile laser offers extensive material compatibility, allowing direct etching on glass without the need for additional materials. With its impressive 55W power, it can etch glass quickly and efficiently, completing projects at 6-12 times the speed of other laser machines. With a solid average rating of 4.5 out of 5, this machine combines power, precision, and reliability, making it a favorite among hobbyist and small business.

WHAT WE LIKE

1. Computer-guided CNC system and fine laser beam control.

2. Computer-controlled operation, the xTool P2 can easily replicate designs with exact precision.

3. Rapid laser beam movement and high-speed CNC system enable quick tracing of designs on glass.

4. The laser etching process removes only a small amount of material.

5.The xTool P2 eliminates the need for harmful chemicals used in traditional etching methods, making it a safer and more eco-friendly option for glass etching.

COULD BE BETTER

1. The mobile version of XCS software lacks some features.

2. Incompatibility with certain features in Lightburn software.

3. Possible need for adjustment of mirrors/lenses due to transport.

4. Need an accessory for rotary engraving taller glasses.

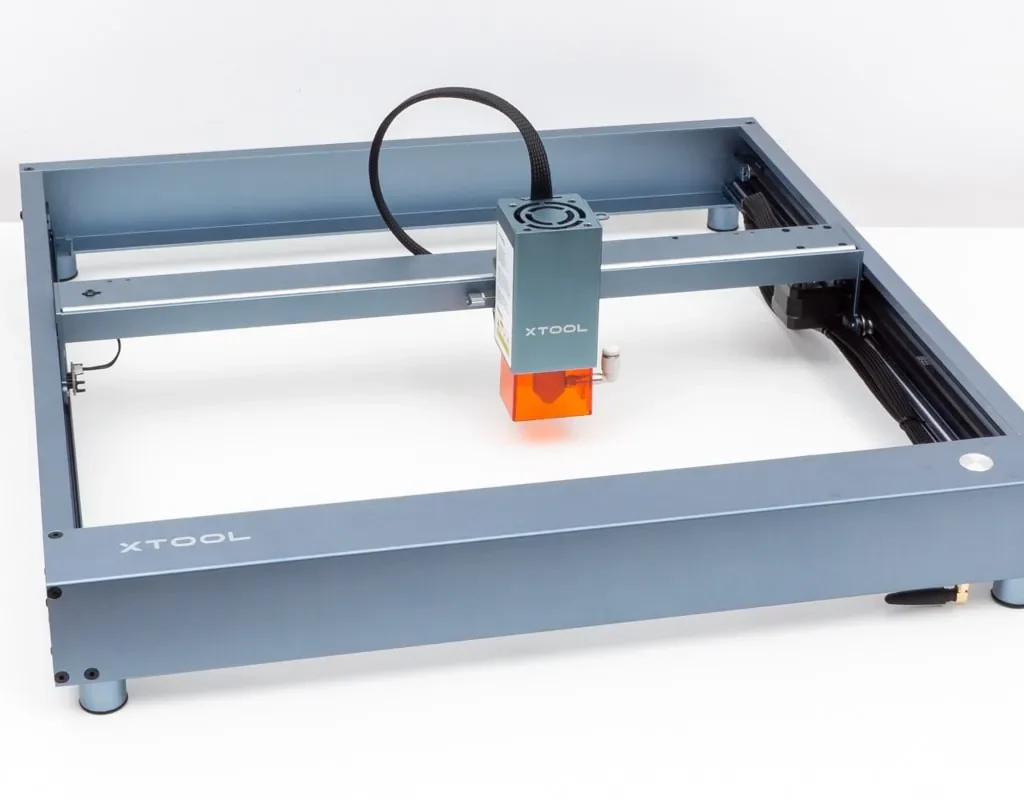

XTOOL D1 PRO – BEST BUDGET GLASS ENGRAVING MACHINE

A Diode laser engraver cannot engrave glass directly, its necessary to use marking paper, and a rotary attachment to rotate the glass. The xTool D1 Pro is a cost-effective and reliable option for glass etching, delivering quality results for users on a budget.

xTool D1 Pro 20W Laser Engraver 120W Laser Cutter,4-in-1 Rotary Roller Kit…

- Infrared Positioning

- Easy Focus Adjustment

- 0.06*0.08mm Ultra-fine Lines

- 0.01mm Motion Accuracy

- 400mm/s Working Speed

- Versatile Software

- Safety Guard

ADVANTAGES

1. Budget-Friendly: The XTool D1 Pro provides an affordable option for glass etching, making it accessible to a wide range of users.

2. Precise and Detailed Engravings: The XTool D1 Pro offers high precision and the ability to produce intricate designs on glass surfaces, ensuring excellent engraving results.

3. Compact and Portable: The compact design of the XTool D1 Pro makes it easy to transport and suitable for small workshop spaces or home use.

DISADVANTAGES

1. Additional Material Requirement: The use of laser marking paper adds an extra step to the glass etching process, requiring the application and removal of the paper for each engraving.

2. Limited Engraving Depth: As a diode laser engraver, the XTool D1 Pro may have limitations in achieving deep engravings on glass compared to CO2 laser engravers.

TECHNIQUES TO ETCH GLASS

Etching glass can be achieved through various methods, including sandblasting, chemical etching, and laser etching.

Sandblasting

Involves using abrasive particles to remove a layer of glass, creating a frosted or textured surface. A stencil or mask is applied to protect certain areas of the glass, allowing for precise patterns or designs.

Chemical etching

Utilizes a chemical solution, like hydrofluoric acid, to react with the glass and remove a layer, resulting in a frosted or textured effect. Stencils or masks are used to protect specific areas.

Laser etching

employs a laser beam to remove a layer of glass, creating a frosted or textured surface. Stencils or masks are applied to shield desired areas from the laser beam.

WHAT IS GLASS ETCHING OR ENGRAVING?

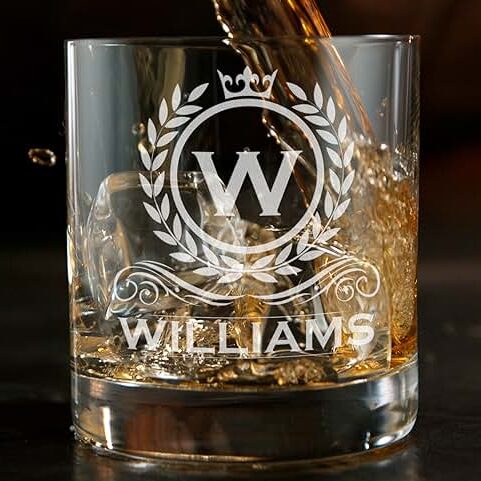

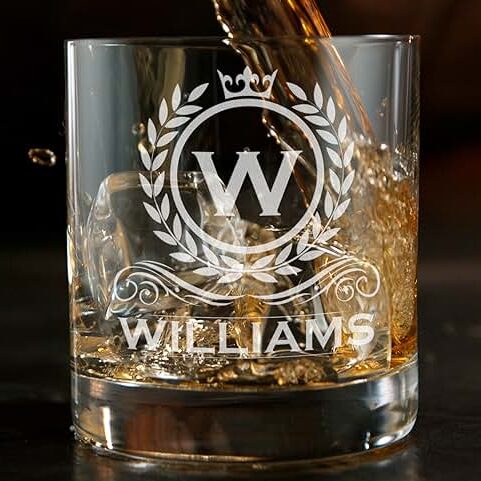

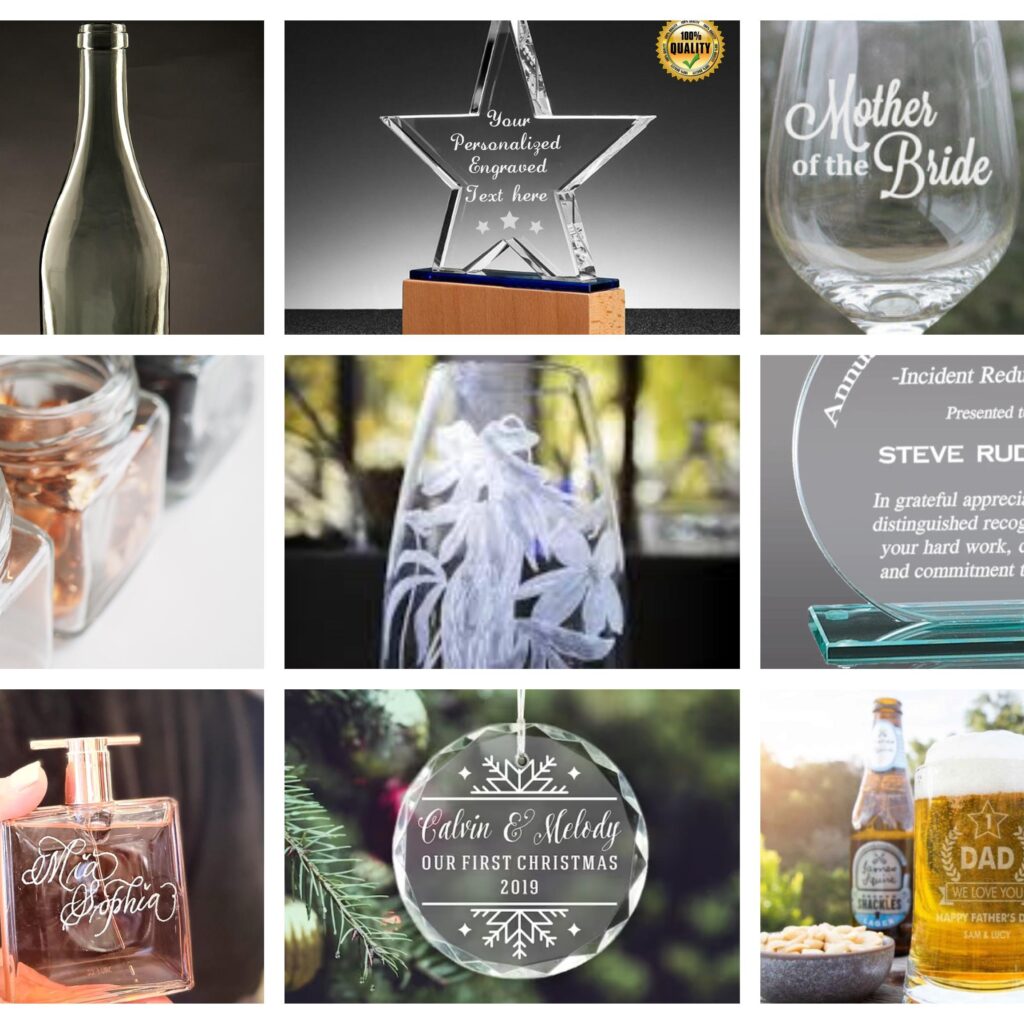

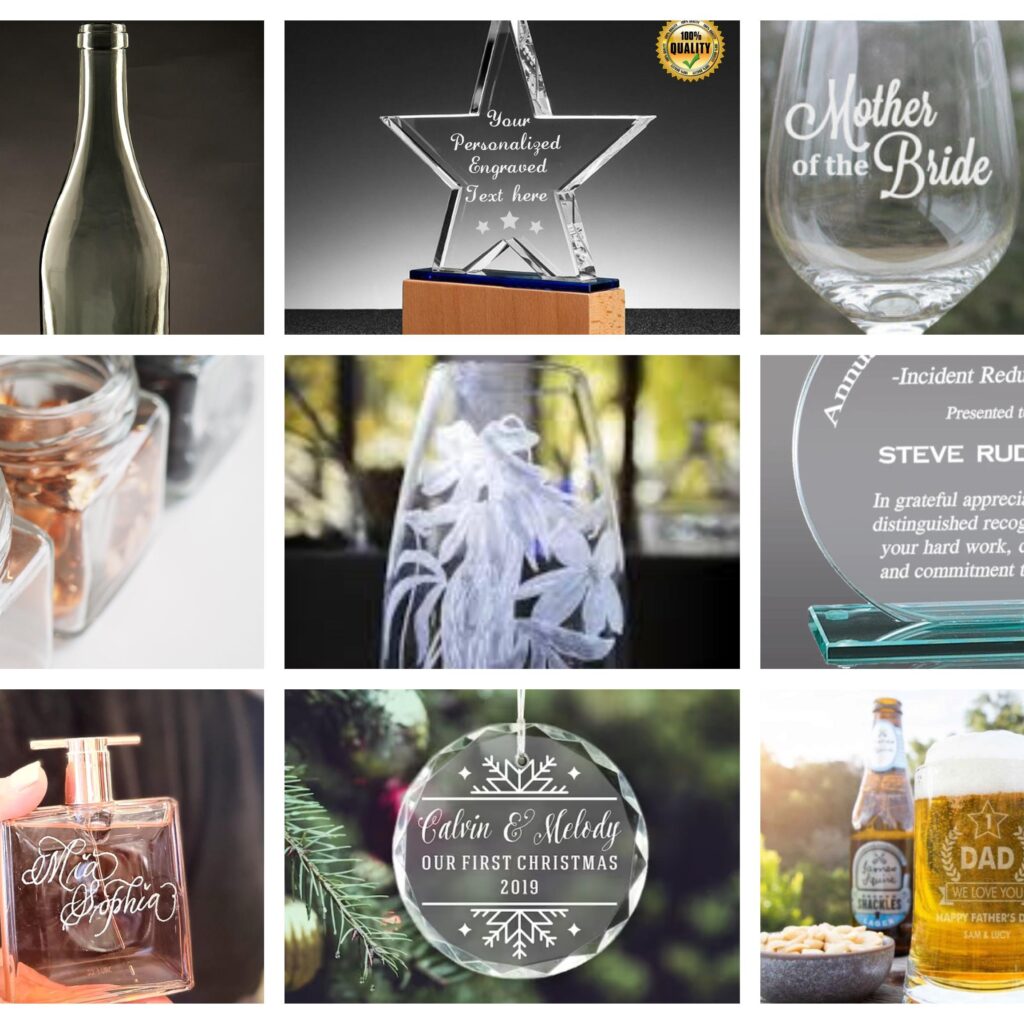

Laser engraving and etching have gained popularity as effective techniques for customizing glassware. From pint glasses to wine bottles, lasers offer precise and beautiful frosted effects for etching logos, designs, and patterns on various glass products.

The Rotary Attachment option simplifies the setup process for engraving different-sized glasses, mugs, vases, and wine bottles by turning the piece as the laser etches the desired pattern. With their ability to implement intricate designs, precise contours, and stunning matte effects, these machines offer a level of detail and craftsmanship that is unparalleled.

WHAT IS THE DIFFERENCE BETWEEN SANDBLASTING AND LASER ETCHING?

Sandblasting and laser engraving are two popular techniques used for etching glass, each with its own pros and cons. Sandblasting is preferred for its sharp and bright engraving with a smooth finish, while laser engraving offers precision, versatility, and ease of maintenance. The choice between the two techniques depends on the specific requirements of the project, including the desired design, opacity, and budget.

Sandblasting:

Advantages

1. Exceptionally sharp, crisp, and bright engraving with a smooth finish.

2. Allows for the creation of different levels of opacity, including gradients in a single piece of glass.

3. Offers a wide variety of readily available designs.

4. Suitable for manual processes and smaller-scale projects.

Disadvantages

1. High mechanical stress can potentially damage the glass depending on the abrasive agent used.

2. Requires regular maintenance and cleaning due to the collection of fingerprints and smudges.

3. Can be expensive, especially for intricate or custom designs.

Laser Engraving:

Advantages

1. No material wear, as the laser does not cause any physical damage to the glass.

2. Precise and accurate engraving, allowing for intricate designs and fine details.

3. Suitable for large quantities of glassware, acrylic, plastic, and metal engraving.

4. Minimal maintenance required.

Disadvantages

1. May not offer the same level of opacity and gradients as sandblasting.

2. Initial investment in laser engraving equipment can be costly.

3. Limited to the capabilities of the laser, such as the size and depth of the engraving.

HOW TO CHOOSE A CRYSTAL & GLASS ENGRAVING MACHINE

Selecting the right laser engraving machine for your glass projects is crucial to achieving exceptional results. Consider these key factors to ensure a well-informed decision:

- Power and precision: Opt for a machine with sufficient power output and precise control settings to achieve intricate and flawless engravings.

- Compatibility and software support: Choose a laser engraver that is compatible with engraving software and offers continuous technical support.

- Build quality and durability: Look for a machine with a sturdy construction and reliable components to ensure long-lasting performance.

- Safety features: Prioritize the safety of both the operator and the glass by selecting a machine with built-in safety measures, such as protective enclosures and emergency stop buttons.

HOW TO LASER ENGRAVE GLASS

Laser engraving glass requires a systematic approach to achieve optimal results. Follow these basic steps to master glass engraving:

1. Prepare the Glass: Choose the right type of glass and clean the surface to remove any dirt or fingerprints.

2. Design Creation and Import: Create or import your design using graphic design software and save it in a compatible file format.

3. Choose Laser Settings: Determine the appropriate power and speed settings for your desired etching depth.

4. Safety Precautions: Wear protective gear and ensure proper ventilation in your workspace.

5. Etching Process: Position the glass, focus the laser, and start the etching process, monitoring it closely for desired results.

6. Cleanup and Finishing: Remove the glass, clean the etched surface, and inspect the results for any adjustments or re-etching if necessary.

TYPES OF GLASS USED FOR LASER ENGRAVING

Not all glass is created equal when it comes to laser engraving. While standard glass is commonly used, crystal glass may produce irregular designs due to its composition. Additionally, alternative techniques like sandblasting can be employed for certain glass types to achieve desired effects.

Some common items for engraving include: Wine or shot glassware, beer mugs, champagne flutes, glass plaques or frames, glass plates, vases, jars, and bottles, christmas ornaments, personalized glass gifts, glass awards, and mirrors.

HERE ARE SOME TIPS AND TRICKS FOR LASER ETCHING GLASS:

- Test different glass types with varying speeds and power settings.

- Applying a moist paper towel over the engraving area can mitigate chipping and create a smooth, frosted appearance.

- Alternatively, you can apply a thin layer of dish soap to the target area and etch the glass while it’s still wet.

- When etching mirrors, engrave on the reverse side using the inverse of the image file to ensure it appears correct in the mirror.

- For glass with a consistent curve like bottles, you can use a roller or chuck rotary attachment for optimal etching.

- For photo engraving on glass, consider using PhotoGRAV, a laser software that offers ideal photo processing on various materials, including glass.