THE BASICS OF LASER ENGRAVING

A BEGINNER’S GUIDE TO LASER ENGRAVING AND CUTTING MACHINES

Are you curious about the fascinating world of laser engraving? Whether you’re a hobbyist, an artist, or an aspiring entrepreneur, understanding the basics of laser engraving is the first step towards unlocking limitless creative possibilities. So, let’s dive in and explore the ins and outs of laser engraving!

HOW LASER ENGRAVING WORKS

Laser engraving is a precise and versatile technique that uses a concentrated beam of light to etch designs onto various materials. By harnessing the power of lasers, it’s possible to create intricate patterns, custom designs, and personalized engravings with exceptional precision.

TYPES OF LASER ENGRAVING MACHINES

Laser engraving machines come in different types, each with its own advantages and disadvantages.

Diode Laser Machines

Diode laser machines use semiconductor diodes as the laser source. They are compact and affordable, making them suitable for small-scale engraving projects. Diode lasers operate at a lower power level, typically between 1 to 20 watts, making them ideal for engraving on materials like wood, acrylic, and leather.

Advantages

They have a longer lifespan compared to other laser types and require minimal maintenance. Diode lasers are also energy-efficient and consume less power. They are portable and can be easily transported or moved within a workspace.

Disadvantages

Diode laser machines have limitations in terms of the materials they can engrave. They are not suitable for engraving on metals or hard materials. The engraving speed is relatively slower compared to other laser types.

CO2 Laser Machines:

CO2 lasers operate at higher power levels, typically ranging from 20 to 150 watts, enabling them to engrave and cut through a wide range of materials, including wood, acrylic, glass, leather, fabric, and some metals.

Advantages

CO2 laser machines offer excellent engraving and cutting capabilities on both organic and inorganic materials. They have a longer focal length, allowing them to engrave deeper into materials. CO2 lasers can achieve high engraving speeds and are suitable for large-scale production.

Disadvantages

CO2 laser machines require regular maintenance and alignment. The laser tube has a limited lifespan and needs replacement after a certain number of hours of use.

Fiber Laser Machines

Advantages

Fiber laser machines offer exceptional precision and speed, making them ideal for intricate and high-detail engraving. They have a longer lifespan compared to other laser types and require minimal maintenance. They can be engraved on reflective and transparent materials with ease.

Disadvantages

Fiber laser machines are generally more expensive compared to diode and CO2 laser machines. They are primarily used for industrial applications and may not be suitable for small-scale or hobbyist use.

MODELS OF LASER ENGRAVING MACHINES

Understanding the different models can help you make an informed decision for your engraving projects. The choice of model often depends on the type of laser used. Here are a few common models:

01.

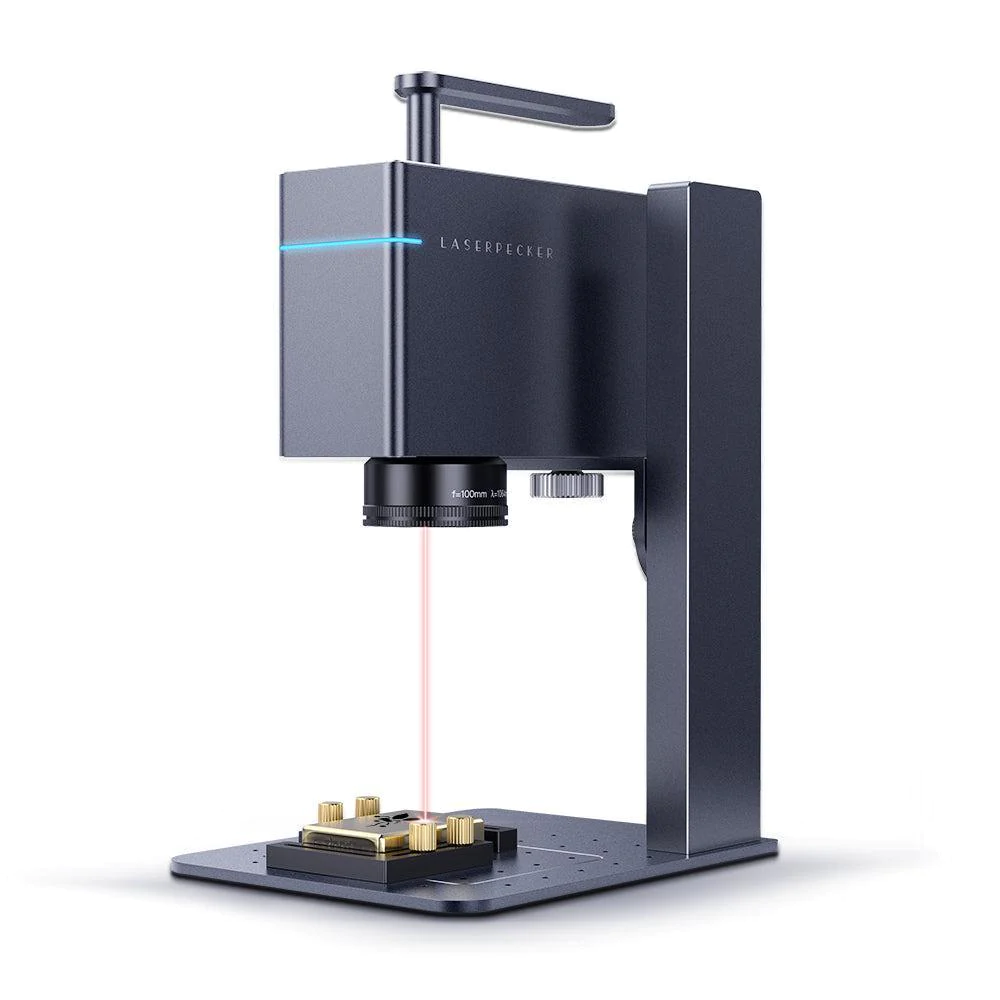

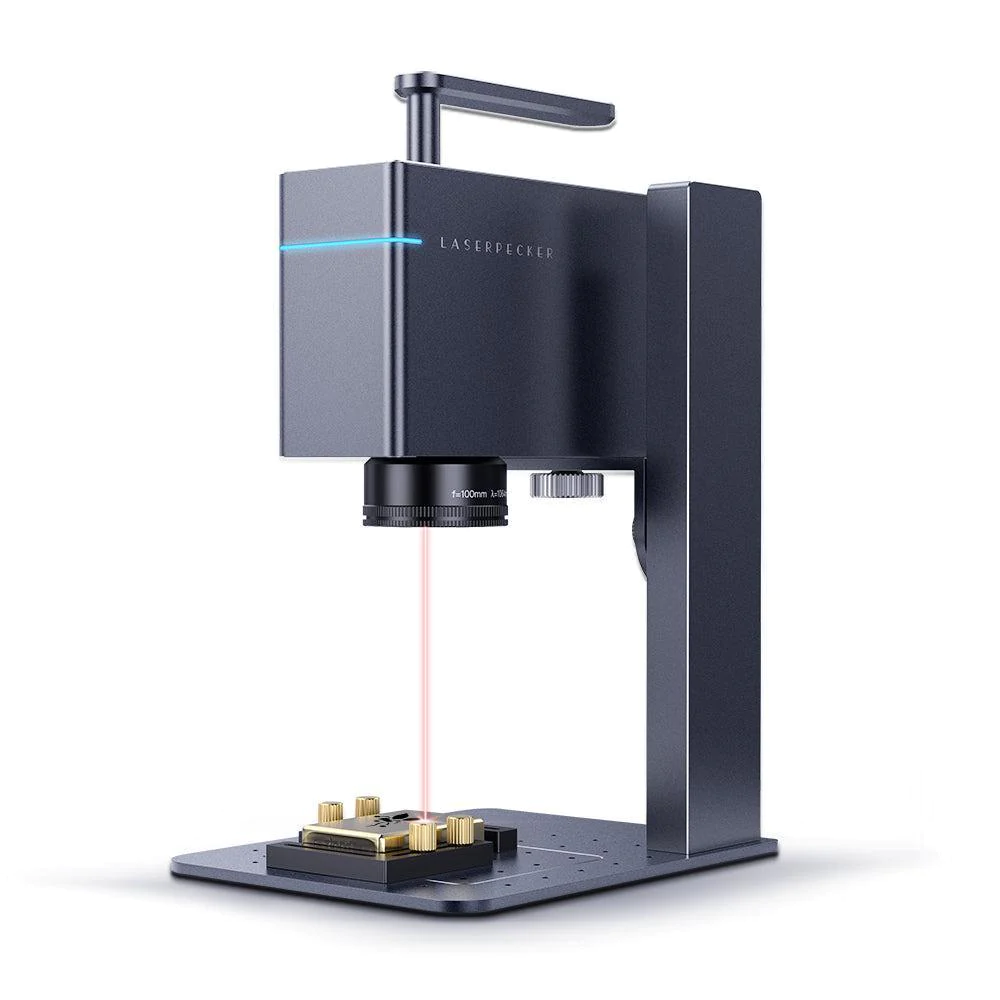

Desktop Laser Engravers

These machines are designed for small-scale engraving tasks and are ideal for hobbyists, small businesses, or home use.

They are compact, easy to operate, and offer decent engraving speed and accuracy.

02.

Portable/Mini Laser Engravers

These models are even more compact and lightweight than desktop engravers, making them highly portable.

They are perfect for on-the-go engraving tasks and can be easily carried to different locations. However, their engraving area and power might be limited compared to larger models.

03.

Handheld Laser Engravers

These engravers offer the ultimate flexibility and convenience as they can be operated by hand. They are typically battery-powered and allow you to engrave on various surfaces, including metal, wood, and plastic, with precision and ease.

03.

Industrial Laser Engravers

These machines are heavy-duty and designed for large-scale engraving projects. They are equipped with powerful lasers and have a larger working area, allowing you to engrave on a wide range of materials with high precision and speed.

Industrial engravers are commonly used in manufacturing, signage, and customization industries.

SAFETY TIPS FOR LASER ENGRAVING

Safety tips to keep in mind when working with laser engraving machines:

1. Always wear appropriate protective gear, including safety glasses and gloves.

2. Ensure proper ventilation in your workspace to minimize the risk of fumes and odors.

3. Familiarize yourself with the specific safety guidelines provided by the manufacturer of your laser engraving machine.

4. Keep a fire extinguisher nearby and never leave the machine unattended during operation.

5. Regularly inspect and maintain your machine to ensure its optimal performance and safety.

PROJECT IDEAS

Looking for inspiration for your next laser engraving project? We’ve compiled a collection of exciting project ideas that showcase the versatility of laser engraving. From personalized gifts and home décor to custom signage and promotional items, let your creativity soar with laser engraving.

LIGHTBURN SOFTWARE AND DESIGNING LASER ENGRAVING PROJECTS

What is LightBurn Software?

LightBurn software is a powerful tool that enables you to control and design laser engraving projects with ease. It is compatible with various laser engravers, making it a versatile choice for both beginners and experts. With its user-friendly interface and extensive features, LightBurn has gained popularity among laser engraving enthusiasts worldwide.

Designing Laser Engraving Projects

Designing laser engraving projects can be an exciting and rewarding experience. Here’s a step-by-step guide to help you get started:

Step 1: Choose Your Design

Before diving into LightBurn software, you need to have a clear idea of what you want to engrave. Whether it’s a custom logo, a personalized gift, or a decorative pattern, take some time to brainstorm and sketch your design on paper.

Step 2: Prepare Your Image

If you have a digital image or a vector file, you’re one step ahead. LightBurn supports various file formats, including JPEG, PNG, SVG, and DXF. If your design is a physical object, you can use a scanner or a digital camera to capture it and then convert it into a digital format using image editing software.

Step 3: Import and Edit Your Design in LightBurn

Once you have your image ready, import it into LightBurn software. This is where the magic happens! LightBurn provides a range of editing tools to fine-tune your design, such as resizing, rotating, mirroring, and adding text. Take your time to experiment and make adjustments until you’re satisfied with the result.

Step 4: Set Parameters and Preview

Now it’s time to define the engraving parameters. LightBurn allows you to adjust the laser power, speed, and depth to achieve the desired effect. Don’t forget to select the appropriate material for your project, as different materials require different settings. Once you’re done, preview the engraving to ensure everything looks perfect.

Step 5: Start Laser Engraving

After double-checking your settings, it’s time to bring your design to life! Load your material into the laser engraver and hit the start button in LightBurn software. Sit back and watch in awe as your design comes to life with precision and detail.

Note: This article is for informational purposes only. Always follow safety guidelines and instructions provided by the manufacturer when using laser engravers.

FACTORS TO CONSIDER BEFORE PURCHASING A LASER ENGRAVING MACHINE

Investing in a laser engraving machine requires thoughtful deliberation. We’ll guide you through the crucial factors to keep in mind before making a purchase:

1. Determine the type of materials you plan to work with, as different machines excel at engraving specific materials.

2. Consider the desired laser power and speed settings to ensure compatibility with your intended projects.

3. Evaluate the size and dimensions of the machine to ensure it fits your workspace.

4. Set a realistic budget and explore options that offer the best value for your investment.

5. Be aware of maintenance needs

6. Software compatibility.